Well, I have been busy cutting and positioning, and cutting some more...

I have almost got the engine to sit where I want it, getting it far enough back has been my main concern. I want equal length driveshafts and a straight line through both hubs and the diff if possible. All this means that the things that get in the way will be attended to first, before the position of the motor are finalised.

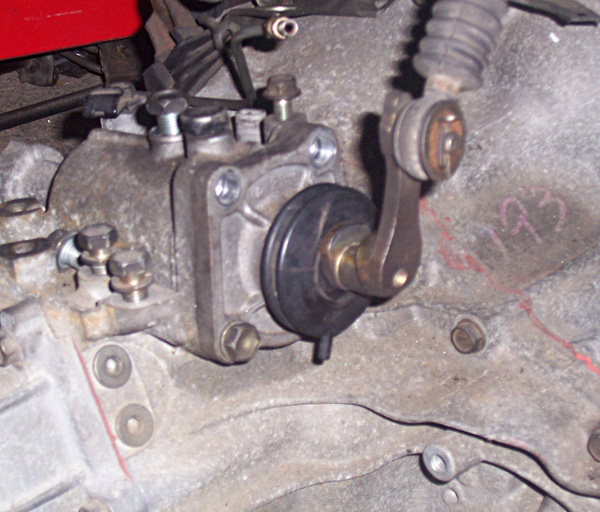

Firstly the the gearshift. It was never going to work as Toyota intended.

This is the across gate. Where it was mounted would have gone right through the left hydrolastic unit. By making a new mount to mount it on the other side, and chopping up the lever I can flip the whole mechanism round so it clears the suspension and still works in its original way. i.e. left for first-second gate, right for 5th - reverse gate.

By removing and dismantling the shifter shaft, it is easy enough to remove 1 spline on the shaft and reassemble everything 180 degrees from where it was. This give more clearance lower, where its needed, but flips 1 axis of your shift pattern. eg. 1st is down instead of up. To rectify this I had planned to use a bellcrank arrangement like 92s (which is very nicely engineered) but I have a cunning plan to do a bit more cross-pollination of the species and get around it with a Honda part.

I have actually nearly finished this part, just need to mount the cable stops and give it a test, but so far it looks promising.

Next up, the water pump...

Madmorrie