Chapter 6 - The Engine Bay

Evening Viewers!

This chapter actually precedes chapters 4 and 5, because all the planning was done before the subframe was actually built. However, if the viewers would allow me some poetic license, then I will put it here. Basically the whole car has been masterplanned, with a place for everything and everything in its place so to speak. But before we get into it, lets start with a couple of truths that I like to adhere to and to answer a question from the viewers.

Truths:

1. Its better to spend 2 hours planning and 1 hour doing than to rush in and then spend 3 hours undoing!!

2. If its worth doing, its worth doing right (the first time!)

Now, one of the viewers asked whether the subrames have been blue plated, and the answer is no. Because, simply, they arent at that stage to be done yet. El Gato isnt on the road yet, and wont be for a couple of months. But in saying all this, let me reassure people who potentially want to copy the QBR subframe, or want QBR to do one for them. We have had the engineer, a gentle, thoughtful and very thorough guy called Gary Bow, along for the journey since day one. Even before we put grinder to steel, a 70-page methodolgy report was submitted for his review and comment. So impressed was Gary, and QBR's attitude to a) getting it right, and b) to having the Engineer involved from the start, that he gave us a long line.

When it came time to inspect the subframe in the car (1st Inspection), the dialogue went something like this (verbatim).

Gary and I were resting on the fenders of the car, looking at the subframe in the engine bay:

Tricky: 'So, what do you think?'

Gary: Very good indeed, shows a lot of thought'

Tricky: 'Umm, do you think its strong enough, do you think it needs any more reinforcing?'

Gary turns to me with an odd expression on his face: 'Do YOU think it needs any more reinforcing?'

Tricky thinking this was a trick question: 'Err, no not really!'

Garry nodding his head: 'Damn straight. Thing could hold up a bloody V8!'

Tricky: (smiles)

Gary gets up from the engine bay and stretches his back: 'Well, see you in a couple of weeks when the engine is in and the engine bay is complete. And remember what I said about braided lines!'

Tricky: 'Sure Gary, I'll give you a call when I am ready''

And that was the first inspection in a nutshell. We'll get tot the second inspection later.

So, masterplanning - what is it and how do you do it. Well simply really. Its just a case of planning where everything will go, before you start to build. With me, I made mock-ups of timber, cardboard or the real thing. How did I know what I would need, fairly simple again, I asked the Engineer. By writing a methodolgy statement and asking him to review it, I had a much greater understanding of what needed to go in, and what didnt. The braided lines where a good example. The Engineer said - 'Do not put braided brake lines in the engine bay. Solid only. I wont pass it if you do!' So, lets plan.

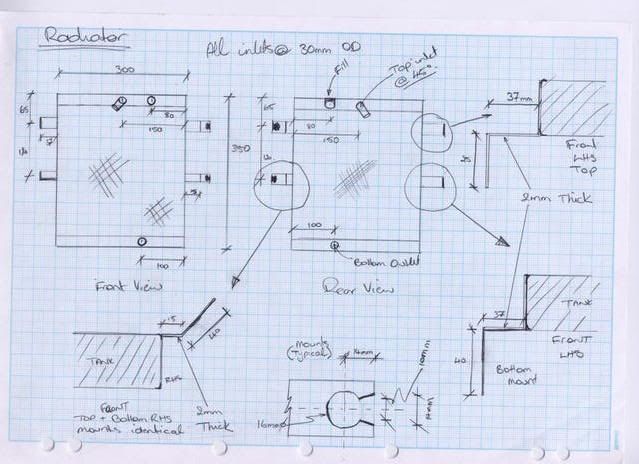

The first thing ever to be designed by me for the Mini was the radiator. It was the most important subsytem, and took up the most dedicated space - right in front! I took some measurements of the available space, and made a mock up of the radiator out of timber to see if it would work. It did! So, from there I sat down and designed the radiator using common core widths and heights. This is what I came up with:

Paul Denooyer from P&F Fabrications was sent the drawing, and this is what came back!

Bloody lovely and the guys from PWR said no worries with cooling at all!

I was informed by the Engineer that my assumption to have boosted brakes was a correct. And uprated boosted brakes at that. So, where to put the booster. the simplest place was over the gearbox, that was where the most space was. To do this I had to make a custom bracket to mount it. It ended up looking like this:

And this is how the booster mounts to the bracket:

And this is where it mounts to. It sits slightly over the gearbox:

Next came the cold air box. I knew where it would go even before I put the engine in. It had to get cold air from outside the engine bay, but actually sit inside the engine bay itself. There was only one place, where the old Mini radiator once lived. I made a mock-up of the box out of MDF, and then checked it for fit etc. Believe it or not it holds over 6 litres. It will act as a plug for when I make it out of carbon fibre, with a removable lid. A K&N filter will sit inside, and it will be ram-air fed from the front of the car, through a duct in the front spoiler. Why have I gone to such lengths when a pod filter would be so much easier. The following:

1. Exposed pod filters are illegal in QLD

2. By using a cold air box, it intakes cold air, not warm engine bay air

3. By using an enclosed and sealed airbox, one can force feed it from the slipstream and gain a precious few hp for free.

4. Someone pinched the standard Starlet one from the halfcut before I collected it

The airbox mould (plug actually). The circle shows where the exit path for the compressor intake will be:

Inside the engine bay. Imagine it made of carbon fibre! (strong and light!)

And on the outside. A cover will go on this side about 30mm wide, with a 21/2 inch snout leading to the front. It will also made of carbon fibre. It will be held in place by screws going right through the lid and inside guard. Sealing will be by foam strip. Should gain 3 or 4 hp on the track (ala road bikes etc)

Once those two were taken care of, the fuel pressure regulator (FPR) had to live somewhere. I had decided early on that an aftermarket FPR would be used, to allow spot-on fuel pressures which would aid tuning. I purchased a Sard, rising rate FPR for about $200 from a performance wharehouse. This is where it sits (mainly because it has a gauge, and I wanted the gauge plainly visible), on its own little bracket (drilled for lightenss of course) right above where the fuel lines go down the firewall. This also shows the booster mounted to the firewall:

From the above picture you can see where the coil pack and solenoids will be mounted. Fairly straightforward position! You may also note that the bracket for the clutch line has been cut off the Starlet half-cut and welded into the Mini engine bay.

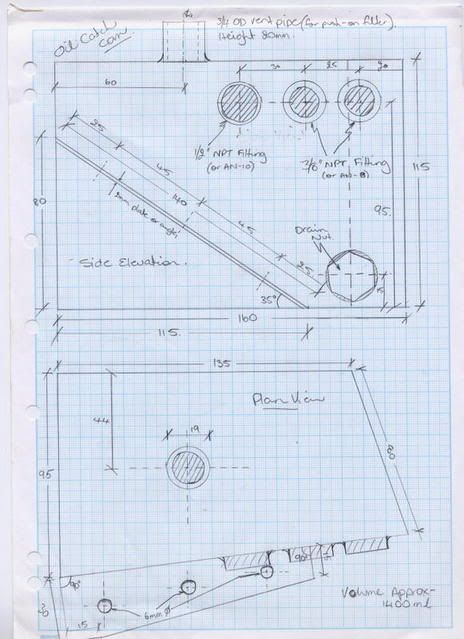

I had decided that the Starlet might need some bling. So I decided to design an oil catch can for the engine bay. It would sit above the drivers side tower. The design was very unorthadox, but looked very good in the end. Once again, Paul Denooyer from P&F Fabrications did the work. here is the drawing I sent him.

And this is what came back - 'BLING'....

Next in Chapter 7 - We finish off the engine bay and tie it all together (and add a bit more 'bling' besides).....