I drove around Perth just before Christmas getting some local quotes and have been quite shocked at the quotes I've been getting for fabricating the radiator and intercooler. The 3 quotes ranged over $780-950 for the radiator and $600+ for the intercooler so I'm also getting some quotes from overseas to get them fabricated.

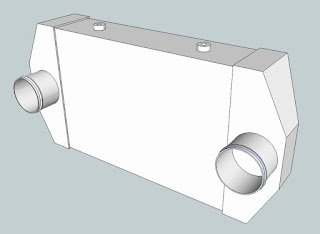

The intercooler will be front mounted under the slam panel - sized at 370W x 180H x 60mm about 20% larger than the factory one - but the biggest improvement will be from being front mounted as opposed to the factory top mount position. There will also be my own electronic intercooler water spray controller installed too which I have used before on a previous car and it improves intake temperatures heaps.

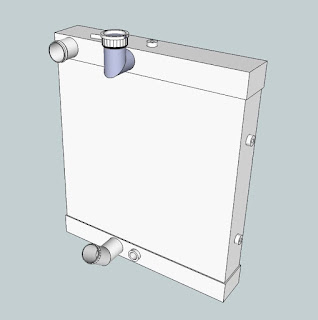

The design of the radiator has been tweaked slightly to stop the lower hose fouling against the (Davies Craig) thermofan, and the upper hose inlet has been moved to allow room to fit an inline temperature sender adapter in the hose.

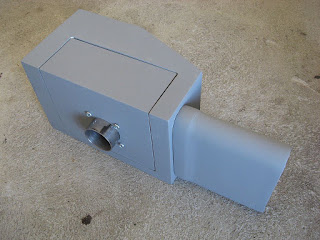

Here are a couple of pics of the final designs (both pics are not the same scale)

I had purchased a HKS adjustable wastegate actuator and when I installed it, I found when using the bracket that was supplied with it, the actuator sat in a different position to the factory wastegate actuator. The actuator diaphragm casing was too close to the front panel, and the actuator inlet was going to foul against the back of the front mount intercooler I designed.

So I made a new mounting bracket similar to the HKS one. Here is the new mounting plate compared against the HKS mounting plate (both bolted onto the turbo compressor housing).

A side effect of moving the actuator closer to the turbo is that the rod no longer lines up with the wastegate connection.

This was easily solved by cutting the rod and welding in a new section of rod with a slight dog-leg in it.

While I had the turbo off, I figured I'd get the tubular exhaust manifold ceramic coated and fit that as well but I wanted the new manifold hidden and had long since thrown out the factory manifold heat shield. I made one out of some 0.8mm steel from an old cabinet I cut up.

The factory manifold has three bolt mounts on it but the aftermarket one only had a single hole, so I had to weld some upright rods with nuts to allow me to mount the sheet on it. With no factory shield to compare it to, I used a nominal clearance of ~10mm between the sheet and the manifold tubes.

The end product, which will be blasted and painted.