Once again, here are a few updates form the last few months...

My focus is now on the interior of the Mini and I wanted to make a centre console to hide the gear shifter. Before that, I had to move the handbrake rearward as it was too close to the gear shifter assembly.

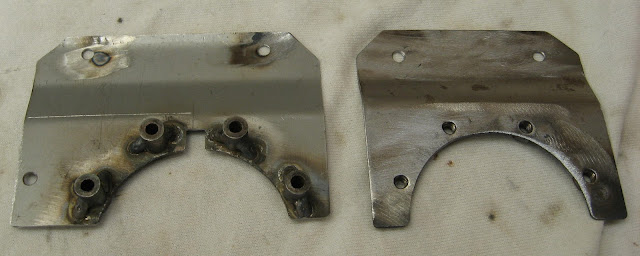

I cut off the factory bent-steel mount and made a beefier one (with captive nuts) that won't eventually crack like a lot of mounts I've seen.

This was stitch welded back on 50mm further back

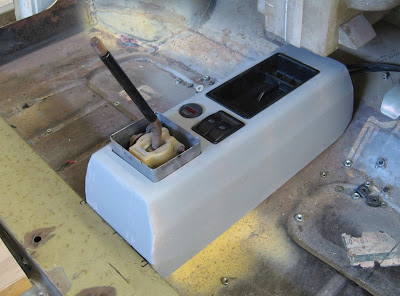

At 150mm wide, I purposely made the centre console as narrow as possible to maximise legroom. It was a basic design made from MDF and covered in a few layers of fibreglass to make the surface more resistant to knocks/dents.

For mounting the gear shifter boot, I made a frame that screws to the inside of the centre console. The boot will eventually screw into this frame

In the console, I have a voltmeter, power window switches and a small plastic storage tray (from a Toyota Tacoma)

The original plan was to have a cigarette lighter and USB outlets in the console but I didn't end up with enough room so I mounted them either side of the stereo.

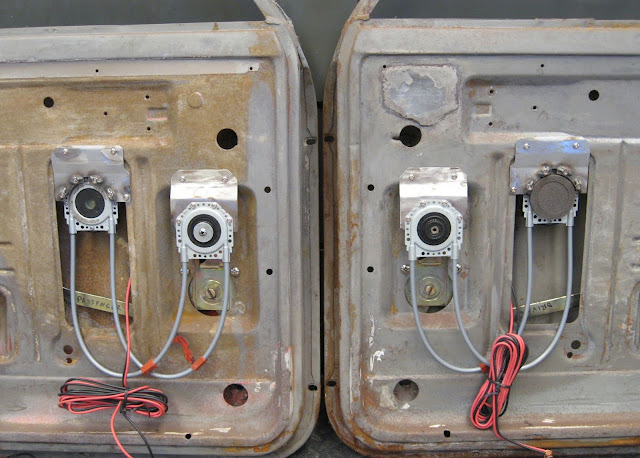

...and speaking of power windows, I bought a SPAL power window kit years ago and it was now time to install the motors. With one end of the motor mechanism attached to the window winder, the other end would fit nicely in the door skin opening and not interfere with the window glass or mechanism as the motor would sit directly below the 1/4 window in the door.

I had to make a custom spacer to stop the handle adapter cog thing from moving back/forth on the winder shaft

Like most power window kits, they come with those triangular / cheese wedge brackets but I wanted something neater than self tapping screws into the door so some more custom brackets were made

Mounted like this (screwed into rivnuts in the door) , apart from the winder handle that sticks out about 40mm, the rest of the power window mechanism only sits at most 5-6mm proud of the door skin and and no cutting of the door required.

_________________

-Alan

I blame my dad for my love of minis. I think I was conceived in the back seat of one

I also blame my Dad for me being 6' 1" - not really the optimum height for driving a Mini.