I decided to make this tool so I could remove the outrigger bearing outer ring from the flywheel housing without destroying it by welding etc.

NOTE: Dimensions shown suit the A series 4 synchro flywheel housing, with the LATEST size RHP bearing outer ring, (34mm bore).

Earlier bearings (now NLA) were smaller ID (33.37mm bore).

---------

---------

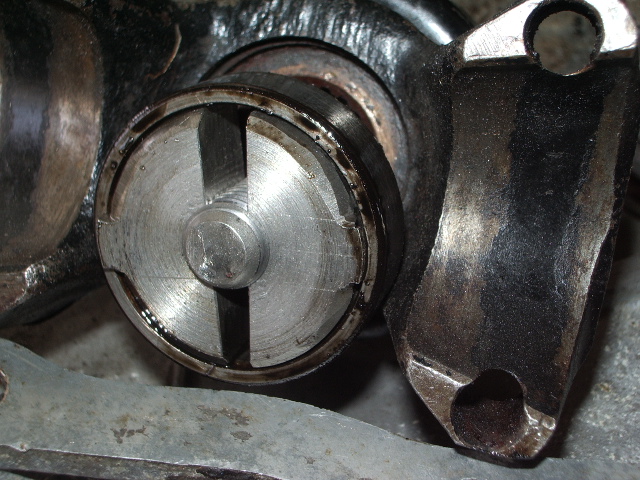

Note the bearing ring is shown there after extraction.

---------

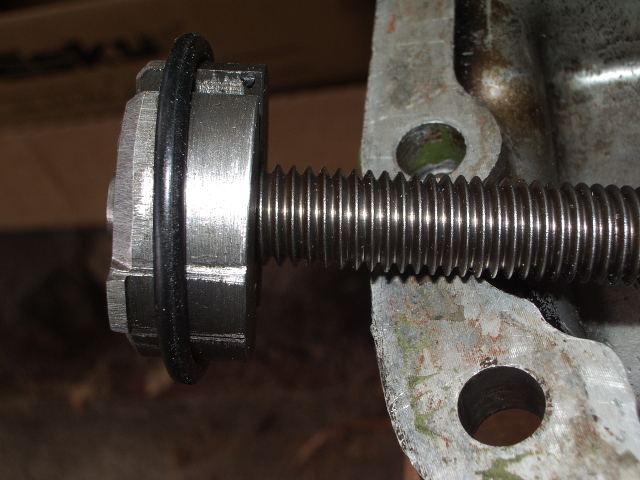

Note the O-ring is just to keep collets together after use.

Sorry no can do a CAD drawing, but here are the machining details:

Material- 1045 or better.

Turn collets in 1 piece, body diameter 34.0mm x 13mm long.

Shoulder turn 36mm diameter x 2.2mm long.

Drill & tap right through, M12 x 1.75

Split in two, with a 5mm gap. I used a 5mm slot drill in the mill.

Mill 2 lugs 7mm wide on the flange. Cut away the rest of the flange, I used the bench grinder.

Put a 2.5mm x 45deg chamfer all round, between the 2 lugs. I used the bench grinder. (it's only for clearance)

To use, drop the collets into the bearing, check they are level with each other and the 2 lugs are in the slots, and screw the stud right in. Then drop a Mini drive yoke over it, fit washer and tighten nut. You could make up an outer body instead, but this works fine.

I warm the alloy housing to ~200C with a hot air gun to reduce drag, but these rings are not fitted real tight.

[edit] typo

[edit 2]-

This tool MUST be hardened, I bent the 2 lugs off mine this week. The bearing ring was very tight due to previous case butchery at the circlip.

_________________

DrMini- 1970 wasaMatic 1360, Mk1S crank, 86.6HP (ATW) =~125 @ crank, 45 Dellorto (38 chokes), RE282 sprint cam, 1.5 rockers, 11.0:1 C/R.