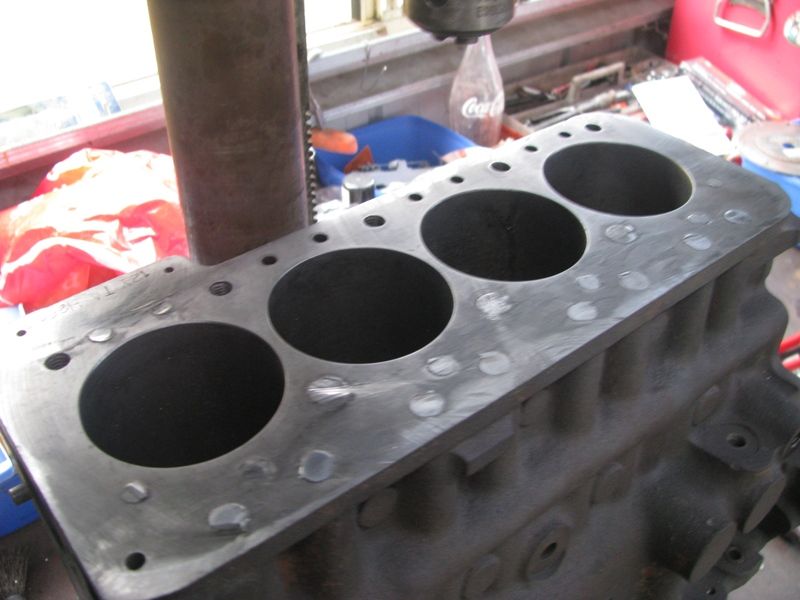

Holes in the block, tapped ready for plugging.

Cam shaft de-lobed.

| ausmini https://www.ausmini.com/forums/ |

|

| Phase two of Clubman Project "Twinky" https://www.ausmini.com/forums/viewtopic.php?f=5&t=77313 |

Page 2 of 19 |

| Author: | paul_ewins [ Sat Jun 30, 2012 1:55 pm ] |

| Post subject: | |

I was using a 2.9 with a mild 1100 and was quite happy. Combined with the standard ratios you ended up with a more useful first gear and a nice relaxed top gear and a car that was a lot quieter on a highway trip. However if you are building a motor that is happy to rev then maybe a diff ratio that allows it to rev would be a better idea. |

|

| Author: | drmini in aust [ Sat Jun 30, 2012 1:57 pm ] |

| Post subject: | |

That tapped hole drains the back of the water jacket. Early cars- Morris Minor, M850 etc has a brass tap (petcock) on there. Try and clear the hole before building the motor- a few twist drills, then hit it with a gurney. |

|

| Author: | dalmeny [ Sat Jun 30, 2012 8:01 pm ] |

| Post subject: | |

drmini in aust wrote: That tapped hole drains the back of the water jacket.

Early cars- Morris Minor, M850 etc has a brass tap (petcock) on there. Try and clear the hole before building the motor- a few twist drills, then hit it with a gurney. Thanks Dr, I got that one, but what about the hole that points upwards next to it, it seems to be oil? |

|

| Author: | dalmeny [ Sat Jun 30, 2012 8:15 pm ] |

| Post subject: | |

Holes in the block, tapped ready for plugging.

Cam shaft de-lobed.

|

|

| Author: | drmini in aust [ Sat Jun 30, 2012 9:53 pm ] |

| Post subject: | |

dalmeny wrote: drmini in aust wrote: That tapped hole drains the back of the water jacket. Early cars- Morris Minor, M850 etc has a brass tap (petcock) on there. Try and clear the hole before building the motor- a few twist drills, then hit it with a gurney. Thanks Dr, I got that one, but what about the hole that points upwards next to it, it seems to be oil? Yeah it's in the oil intake to the pump, just screw a plug in as it was originally. NFI what its purpose was. |

|

| Author: | dalmeny [ Wed Jul 11, 2012 11:33 pm ] |

| Post subject: | |

A little more progress. Just in case anyone was wondering I have spoken to Matt Read and he is happy for me to post the picture for this build. Once al the holes were tapped I plugged them all with mild steel bolts and Loctite sealant. The end ones that overlap the new BMW holes. Used Matt Read cast iron plugs.

Then cut them off with a thin cut off wheel.

Off to the engine shop where the block had the deck shaved.

Marked and drilled all the new BMW bolt and water holes.

Next was to tap all the new head bolt holes.

Whilst I was in the drilling mood I relocated the oil feed hole in the head to line up with the mini block.

Back to the questions. Q.10 Has anyone successfully machined out the front of a small bore Primary Gear to take the 1275 bush? Q.11 Has anyone used the full floating front bush from Mini Spares? |

|

| Author: | adamstuart [ Wed Jul 11, 2012 11:42 pm ] |

| Post subject: | |

Is it just me or do some of the studs look out of square? Namely the two of the left hand end? |

|

| Author: | dalmeny [ Wed Jul 11, 2012 11:48 pm ] |

| Post subject: | |

adamstuart wrote: Is it just me or do some of the studs look out of square?

Namely the two of the left hand end? Yeah looks that way but they were only in a couple of threads. Heads been on and all ten bolts wind in nicely. |

|

| Author: | TheMiniMan [ Thu Jul 12, 2012 9:11 am ] |

| Post subject: | |

plenty of people have used small-bore primary gears & had them machined out to suit 1275 - so that`s a big yes & also another yes with the use of full-floating front bush, they work fine, just need to make sure you have enough clearance & also make sure it`s all nice & smoothly pollished surface you`re doing quite well Steve, keep up the good work |

|

| Author: | drmini in aust [ Thu Jul 12, 2012 10:40 am ] |

| Post subject: | |

Yes you can machine out the front primary bush, then take another 1/8" out of the gear's bore to suit the 1275 bush. Floaty MSC bush works fine. But once the bush is gone you need bloody good tooling to bore the gear, it is HARD! I used a ceramic insert, but these are pretty fragile. |

|

| Author: | woodwormm [ Thu Jul 12, 2012 3:54 pm ] |

| Post subject: | |

Ahh, how cute, how many engines out there can you sit on a pedestal drill?! I was wondering if you were using a rotobroach, until i looked harder at the pics I want a twinky.. looking nice. |

|

| Author: | sgc [ Thu Jul 12, 2012 4:18 pm ] |

| Post subject: | |

Shame the machine shop took the engine number off when they decked the block... |

|

| Author: | justfanginaround [ Thu Jul 12, 2012 5:05 pm ] |

| Post subject: | |

sorry i was too slow with my reply |

|

| Author: | dalmeny [ Thu Jul 12, 2012 7:51 pm ] |

| Post subject: | |

drmini in aust wrote: Yes you can machine out the front primary bush, then take another 1/8" out of the gear's bore to suit the 1275 bush. Floaty MSC bush works fine.

But once the bush is gone you need bloody good tooling to bore the gear, it is HARD! I used a ceramic insert, but these are pretty fragile. Dr. Is that 1/8" an exact and accurate mearsurement for the 1275 bush, or is it an approximate and it needs to be machined to suit the bush? |

|

| Author: | dalmeny [ Thu Jul 12, 2012 7:54 pm ] |

| Post subject: | |

sgc wrote: Shame the machine shop took the engine number off when they decked the block...

Knew it was going to happen. The BMW head covers it anyway. There has been a surface prepared on the front of the block, at right angles to where it used to be. |

|

| Page 2 of 19 | All times are UTC + 10 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|