justfanginaround wrote:

sorry i was too slow with my reply

The crankcase breather????????

| ausmini https://www.ausmini.com/forums/ |

|

| Phase two of Clubman Project "Twinky" https://www.ausmini.com/forums/viewtopic.php?f=5&t=77313 |

Page 3 of 19 |

| Author: | drmini in aust [ Thu Jul 12, 2012 7:57 pm ] |

| Post subject: | |

dalmeny wrote: drmini in aust wrote: Yes you can machine out the front primary bush, then take another 1/8" out of the gear's bore to suit the 1275 bush. Floaty MSC bush works fine. But once the bush is gone you need bloody good tooling to bore the gear, it is HARD! I used a ceramic insert, but these are pretty fragile. Dr. Is that 1/8" an exact and accurate mearsurement for the 1275 bush, or is it an approximate and it needs to be machined to suit the bush? 1.750" bore is correct size for a 1275 bush (fixed or floaty).. Note if you fit a standard fixed bush you then need to bore it to fit, as the bore is undersized. Clearance is .003" on the shaft. |

|

| Author: | dalmeny [ Thu Jul 12, 2012 7:58 pm ] |

| Post subject: | |

justfanginaround wrote: sorry i was too slow with my reply

The crankcase breather???????? |

|

| Author: | dalmeny [ Thu Jul 12, 2012 8:05 pm ] |

| Post subject: | |

drmini in aust wrote: dalmeny wrote: drmini in aust wrote: Yes you can machine out the front primary bush, then take another 1/8" out of the gear's bore to suit the 1275 bush. Floaty MSC bush works fine. But once the bush is gone you need bloody good tooling to bore the gear, it is HARD! I used a ceramic insert, but these are pretty fragile. Dr. Is that 1/8" an exact and accurate mearsurement for the 1275 bush, or is it an approximate and it needs to be machined to suit the bush? 1.750" bore is correct size for a 1275 bush (fixed or floaty).. Note if you fit a standard fixed bush you then need to bore it to fit, as the bore is undersized. Clearance is .003" on the shaft. Thanks Dr I'm still leaning towards the heical gears rather than the straight cut, I don't think the small loss of HP over-rides the noise for road use. |

|

| Author: | 69k1100 [ Sun Jul 15, 2012 10:44 pm ] |

| Post subject: | |

Also helical cut gears have a greater contact area, spreading the force between the gears over a greater area = stronger. However (I don't know if minis suffer badly from this) helical cut gears exert thrust, in a high hp situation this may prematurely wear out the thust bearing, and they generate higher oil temps. There is only one type of helical gear that gets around thust and that is the 'herring bone' |

|

| Author: | MrFail [ Mon Jul 16, 2012 5:10 am ] |

| Post subject: | |

69k1100 wrote: Also helical cut gears have a greater contact area, spreading the force between the gears over a greater area = stronger '

Helical gears are stronger than straight cut gears????? That is the first time ive heard someone say that.... Isnt the whole point of SC gears the increased strength over standard helical?? |

|

| Author: | 69k1100 [ Mon Jul 16, 2012 6:05 am ] |

| Post subject: | |

The point to sc gears is less hp loss and reduced thrust loading, makes for a smaller, lighter gearbox. This is given the same pitch/tooth height. If they are comparable gears, same material but one is sc and one is helical the helical will be stronger. |

|

| Author: | drmini in aust [ Mon Jul 16, 2012 11:03 am ] |

| Post subject: | |

69k1100 wrote: The point to sc gears is less hp loss and reduced thrust loading, makes for a smaller, lighter gearbox.

This is given the same pitch/tooth height. If they are comparable gears, same material but one is sc and one is helical the helical will be stronger. The lack of end thrust gives better thrust washer reliability. As for HP gain from SC drops, I'd like to see some documented evidence. My favourite race engine builder reckons there's SFA difference. |

|

| Author: | Mokesta [ Mon Jul 16, 2012 4:26 pm ] |

| Post subject: | |

The articles I have from when the 850 was released say that the decision to put the motor in with carby at the rear at the cost of the additional lay gear in the drop gear train cost 3% drive efficiency. They decided that carby icing and access to the dissy was worth the 3% penalty. So if one extra gear costs 3% then changing the profile of a couple of gears is unlikely to have that sort of effect. I guess a maximum of 2% improvement. Makes a 100Hp motor run like a 102Hp motor. I doubt I could tell the difference when driving but a racer looking for every last Hp may. M |

|

| Author: | kiwiinwgtn [ Mon Jul 16, 2012 8:18 pm ] |

| Post subject: | |

Nice write up and Pics .. |

|

| Author: | dalmeny [ Sat Jul 21, 2012 6:27 pm ] |

| Post subject: | |

A little more progress. Sold a few angus steers and sent to money to "theminiman" for the Twinky kit and extractors. (hope I don't get a few magic beans in return So in the mean time I've been playing around with the oil drains and breathers. Mocked up this system for the back oil drains, and breather. I gutted an old mechanical fuel pump and plumbed it up for the oil returns and one of the breathers. If I don't need the outlet I'll block it off.

If there is a floor in the design I'm sure Matt will let me known. At the rear of the head I had 2 alloy bungs turned up and threaded for the rear oil drain and hot water.

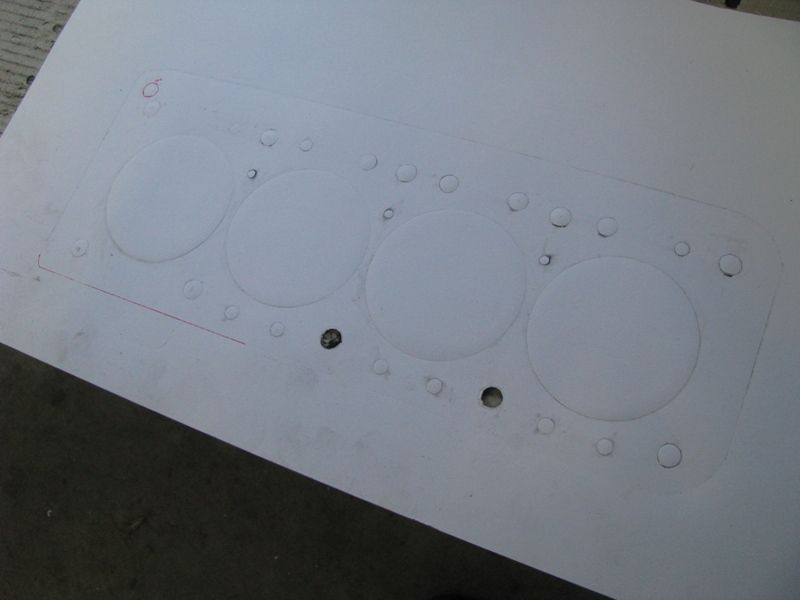

Instead of using a modified mini head gasket I decided to have a custom one made. A gasket manufacturer had quote me approx $150. Template made up and ready to go.

|

|

| Author: | dodge [ Sun Jul 22, 2012 1:11 am ] |

| Post subject: | |

worst set up ever |

|

| Author: | dalmeny [ Sun Jul 22, 2012 12:34 pm ] |

| Post subject: | |

dodge wrote: worst set up ever

Don't just shoot off at the mouth, add some constructive criticism. |

|

| Author: | michaelb [ Sun Jul 22, 2012 1:01 pm ] |

| Post subject: | |

Gotta luv this forum You can just feel the luv in the air I think it looks ingenious, although I may have tried to use metal tubing, and maybe just tapped into the fuel pump plate instead of using the whole pump. But still, ingenious |

|

| Author: | Morris 1100 [ Sun Jul 22, 2012 1:16 pm ] |

| Post subject: | |

The problem I see it you are trying to let air out of the crankcase while trying to let oil drain from the head through the same hole. So the air from the crankcase will probably blow the oil from the head up the pipe into the K&N filter. In my view you will need to separate routes, one for the oil to drain and another for the crankcase to breathe. |

|

| Author: | kiwiinwgtn [ Sun Jul 22, 2012 10:14 pm ] |

| Post subject: | |

a question How much oil does down the hoses. Do you have enough volume in your fuel pump housing to manage the volume of oil. Keep up the good work.. Kiwiinwgtn |

|

| Page 3 of 19 | All times are UTC + 10 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|