Great to see someone else with this head in aus!

This is what I did about not having any vac take offs, we press fitted some tubes in to each port. Note the angle to clear the injectors..

I wasnt convinced this would be enough to run my brake booster so I put a electric vac pump in just for that. It needed a little tank and a home made controller using a GM Map sensor to keep between 15-25" of vac to get a good feel to the brakes and not run the pump to hot.

A few things I have found with mine that you might want to look at are, where the spark plugs are drilled and tapped in to the chamber there becomes a very thin section of the alloy that i had melt and crack. Mine was running with its turbo so maybe the extra heat from that didnt help but something to think about.

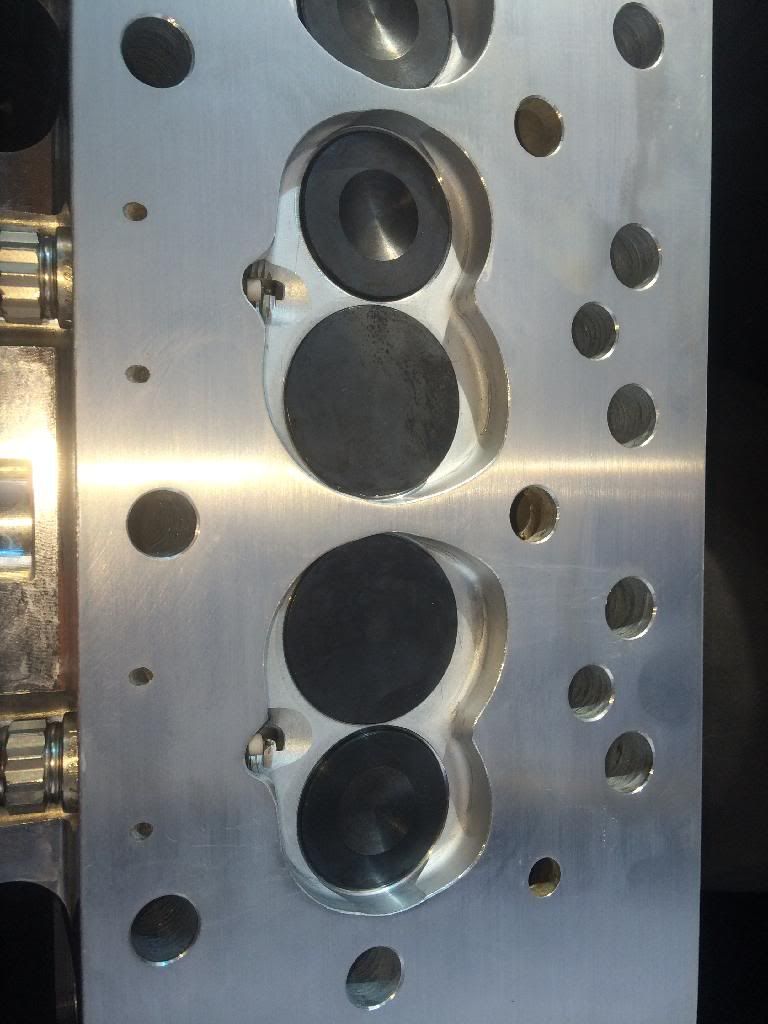

When the Head was new:

After a few 100km inspection

This is what I did to over come it:

One other thing is the heads are very soft, my rocker posts and head studs sunk into the head a little, so re tension the head a few times after its been hot.

I also had the small rocker stud pull the threads out of the head when putting it together the 2nd time. ARP studs using a torque wrench, so we are having to helicoil them atm.

I had had mine flow tested twice after some mods if you are keen on seeing let me know

Thanks Nathan.