I have now fitted my 59 tooth crown wheel to a pot joint diff.

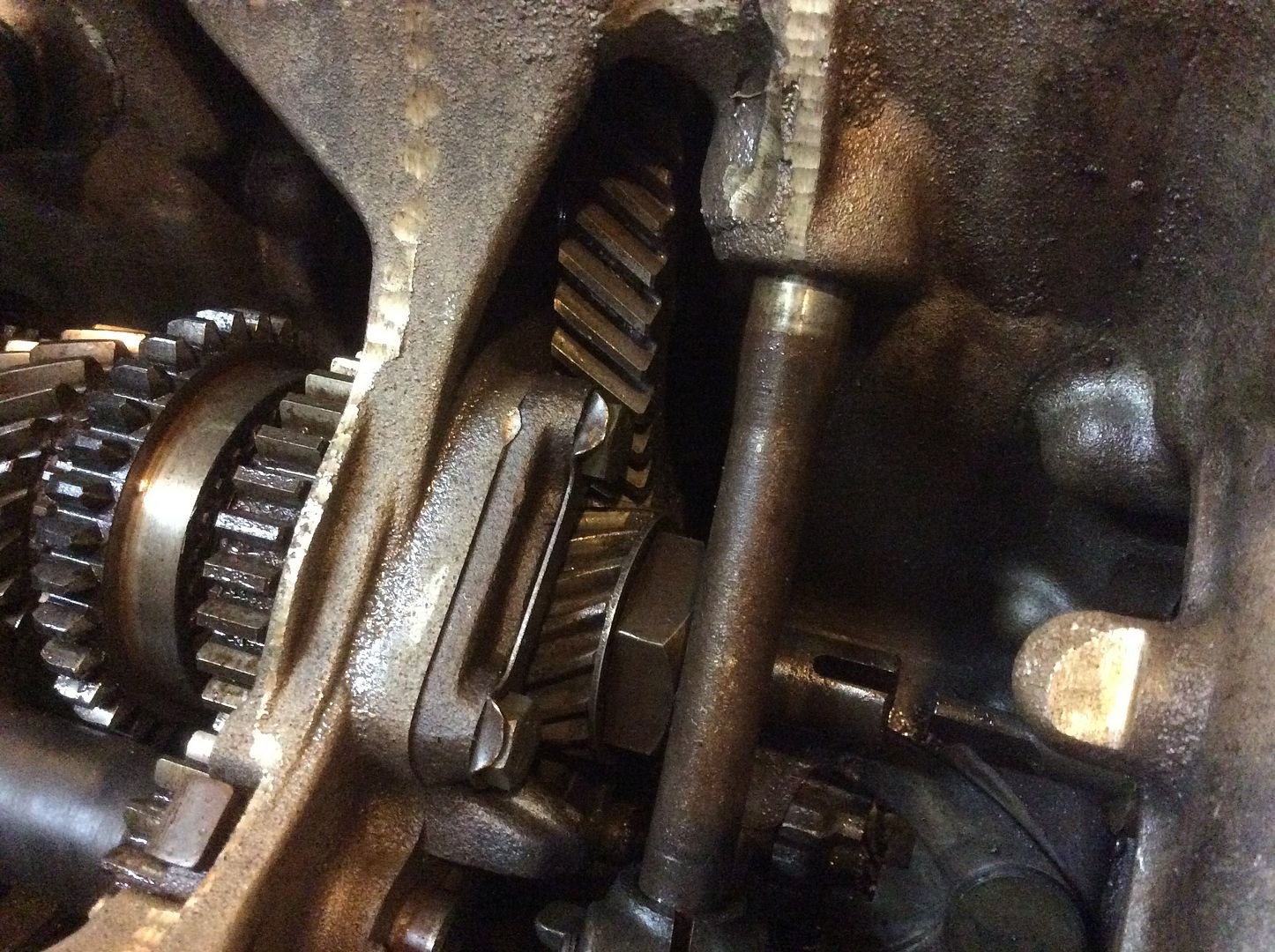

Then I had to lock the G/B to undo the pinion nut.

Locked in 1st & 4th.

With the gearbox upside down and a socket and 1/2" breaker bar, I hit the breaker bar with a 2lb hammer and the nut came loose

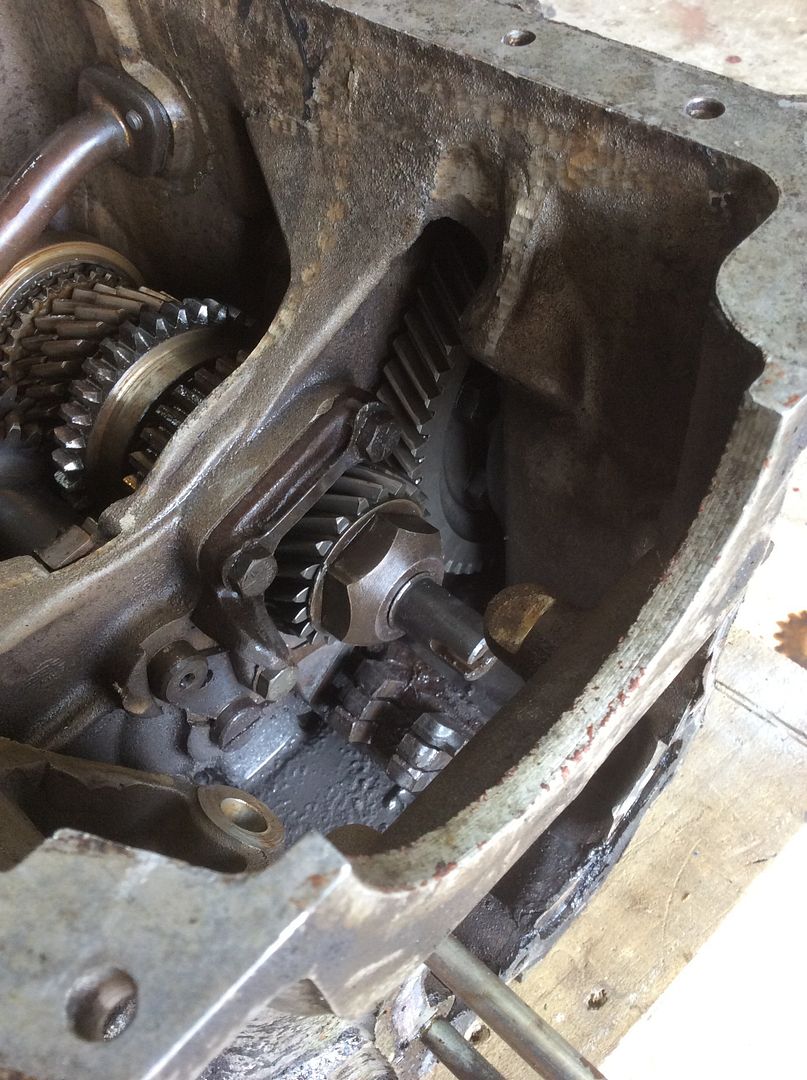

The 3rd motion shaft bearing retainer was too small for the 20 tooth pinion so I put it in my 2 jaw chuck (bench vice) and machined it out to fit the pinion with my manual milling cutter (half round file).

Then mounted the pinion and bearing retainer, fitted the diff and 850 diff housing.

The original pinion was a 17 tooth and was smaller than the locking tab for the pinion.

Before:

With 2.95:1 pinion and crown wheel.

Now that it all seems to work OK, I will completely strip the gearbox for a good clean and check and replace anything necessary.

P.S.

What is the trick to removing the speedo drive gear from the housing.

Mine is stuck

got it out

Can I borrow a set of "tools" to remove the first motion shaft roller bearing (I've removed the circlip) and then the tool to remove the 3rd motion shaft.