This is how to fix your mechanical (capillary) gauge if the needle doesn't move anymore.

I was lucky because my gauge was still very new and it was easy for Dave's (sitnlo62) trained eye to spot the leak. There was a dodgy looking solder from the factory on the bulb end of the gauge. Dave re soldered it and it has been working fine since.

This is what you start with - a gauge that constantly reads 30°C (minimum).

Unsolder the end, the solder is covering a little pin that is inserted into the end of the bulb. Please note, use the lowest wattage soldering iron you can! You do not want to heat the bulb too much.

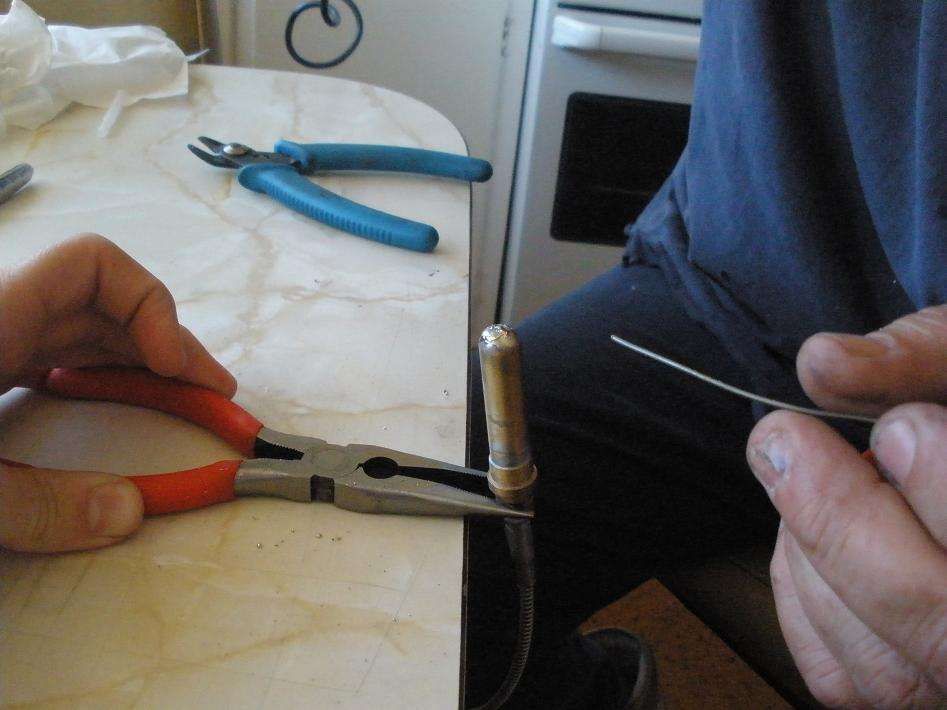

This is it with the pin out. You might have to get some small strong pliers onto the pin as the fit is very tight. If your gauge still has pressure in it be VERY careful. When you apply heat to the bulb it heats the ether creating pressure, this causes the pin to shoot out of the bulb if you do not have a good grip on it. Also be careful of your eyes, ether sprays EVERYWHERE when you pull the pin out.

This is the size of the pin in relation to the adapter that goes in the head. Be careful, the original one that was in my gauge got damaged getting it out so Dave machined up a new pin out of brass to replace it - be aware just in case.

Clean up the end of the bulb (get rid of all the solder)

Looking all clean now.

Clean out the hole, make sure there is no solder in it that will impart putting the pin back in. Dave used a scalpel and a bit of small, tapered brass that I assume was left over from when he machined a new pin.

This is the pin sticking out the top of the bulb, it still needs to be hit in. Dave is checking that there is no damage on the pin before we fill it.

Yummy, ether

Fill the bulb right to the top (as full as it goes).

Put the pin back in as quick as you can.

Hit the pin back in STRAIGHT to avoid damaging the pin. Do not hit the pin all the way in. You want to leave enough sticking out that you can get it out again if need be!

Act quick with the solder, seal it off. The ether was escaping a little as we were doing this.

Soldered up

Bit more to be sure and just to get a nice flow happening with the solder so we didn't end up with many jagged edges.

And hopefully you should end up with this result:

102°C in boiling water. I also check it's accuracy against a thermometer I have here and it read within 2°C of actual. I was happy with that, it's accurate enough that you can tell if your engine is cooking.....

If it isn't spot on, take note of the error and install it. Otherwise, pull it apart and have another go

Thanks to Dave (sitnlo62) for this How To and the use of his kitchen.