With some spare time on my hands at the weekend I thought I would have a look at how the rear bumber might be deseamed and cut out a 1" section

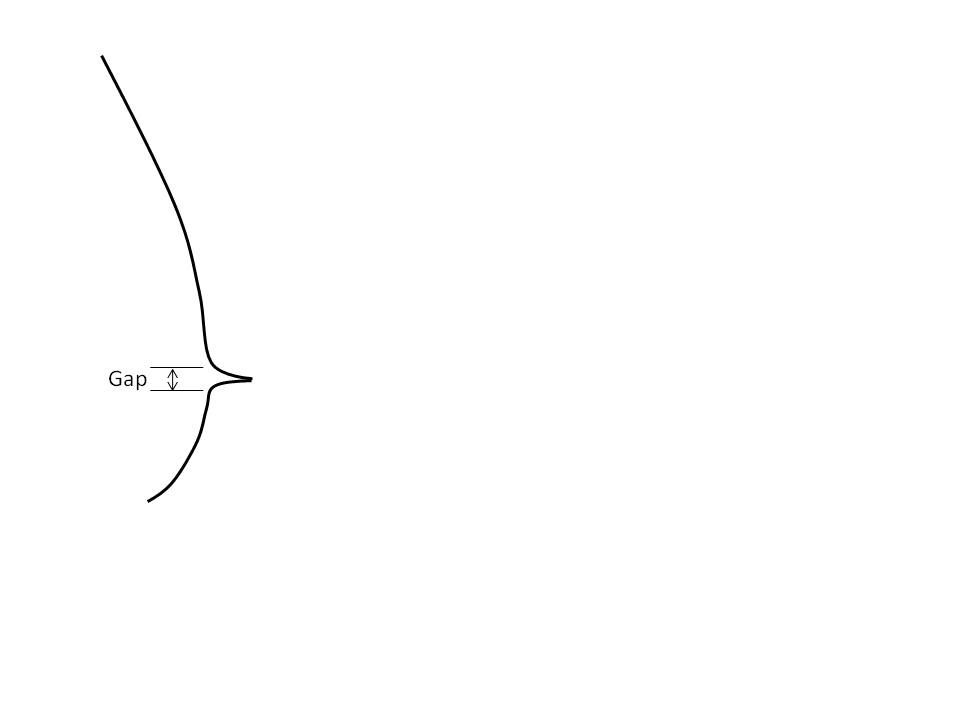

The problem is that the panels don't meet at the back at the tangent point of the panels.

As a result, when you grind the panels flush you get a 2-3 mm gap!!!

What's the secret? Do you have to weld a plate or filler rod at the rear of the panels?