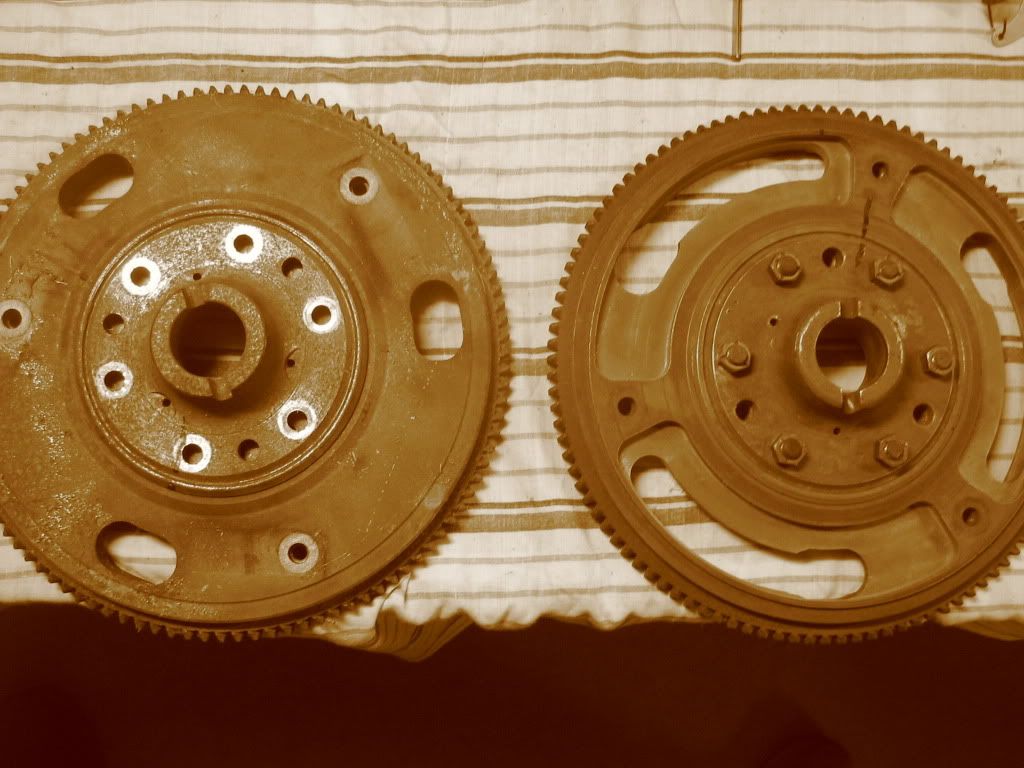

Doc,,, there are literally Hundreds of these (my) lightened flywheels out there, did my first one when i was 16 years old,,, now 47,,, with usually 20 odd machined per year,,, that makes for lots & lots of them now ,,, Not heard of one breaking up (now i`ve hexed myself havn`t i??? ) BUT!!!!!!!!! they`re still retaining the factory thickness in the right spot(s) & no need for extra washers under the straps

they`re qll CNC machined exactly the same,,, if it were balanced before we lighten them then they are pretty well still in balance after we finish ( i always suggest balancing anyways)

They`re not "THIN"

I`m not a fan of just machining them thin,,, Just simply thinning them down tends to make them warp (not a matter of if,,, more a matter of when)

|