I have just rebuilt my engine with a new cam and followers, and new pistons and bearings.

We put it all back together, and started it up fine. It had excellent oil pressure. We ran the cam in for about 25 minutes and then went to put it into gear to move it back into the garage. The engine stopped as soon as the cluch disengaged.

We tried a few times and exactly the same thing happened each time. If you had a few revs on then the engine would slow right down.

I did a quick search on Ausmini for similar symptoms and pretty quickly saw posts which said that a possible culprit was putting the thrust washers in backwards. We decided that it was better to be safe than sorry and pulled the engine back out, split the box off and popped off the centre main cap.

Sure enough the two halves of the washers which are in the actual block side of the crank had been put in backwards.

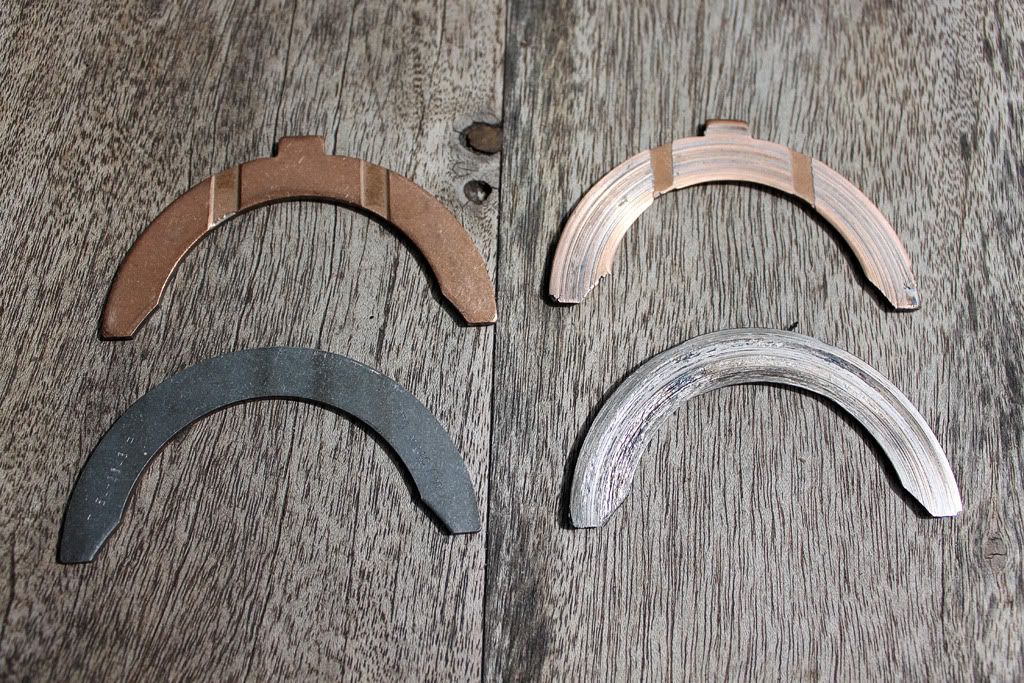

As you can see, the washers which are put under pressure by the clutch mechanism are fairly much rooted. The half which was put in backwards has been severely eroded and the stuff that came off has ripped into the bearing surface of the half that was correctly installed.

Hopefully it hasn't done too much damage apart from the washers themselves. The crank seems okay and I'll take off the oil pump and clean it to be sure.

Aah well, we live and learn.