Could someone please confirm what the correct installed position of the dissy drive is at TDC with 1 on comp stroke.

Two manuals I have seem to contradict one another.

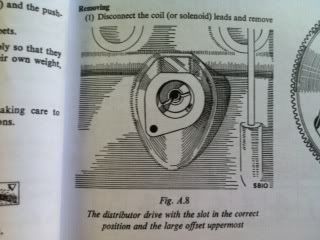

The Leyland manual (black book) says that the illustration (shown below) is the position you need prior to inserting and rotating the drive.

It says to hold the spindle in position shown in Fig A.8 and enter the gear.

The SP manual shows the same illustrated position but states it shows the installed position.

Or perhaps someone could confirm approx where the rotor arm should be pointing at TDC (comp on 1). Mine seems to be at about 1 o'clock.

The reason I ask is that I suspect my dissy is wrongly oriented. Last time I bought a set of leads that were custom length for a mini they were all over the shop.

Cheers