I'm looking after a problem on another member's car. The carb is a mishmash of SU parts and the damper piston doesn't match the carb or damper pot. It jams at the lower end unless the screws are kept loose.

Anyway, its best ot baseline the carb in any case, so I've picked up an old SU from the depths of Morris 1100's dark shed, and I've pulled it down pending a rebuild. It will need a fresh spindle and bushes inserted, and a new jet and needle. I will need to wait a little while for the parts to come in yet.

For today I've pulled it down and run it through the glass bead blaster.

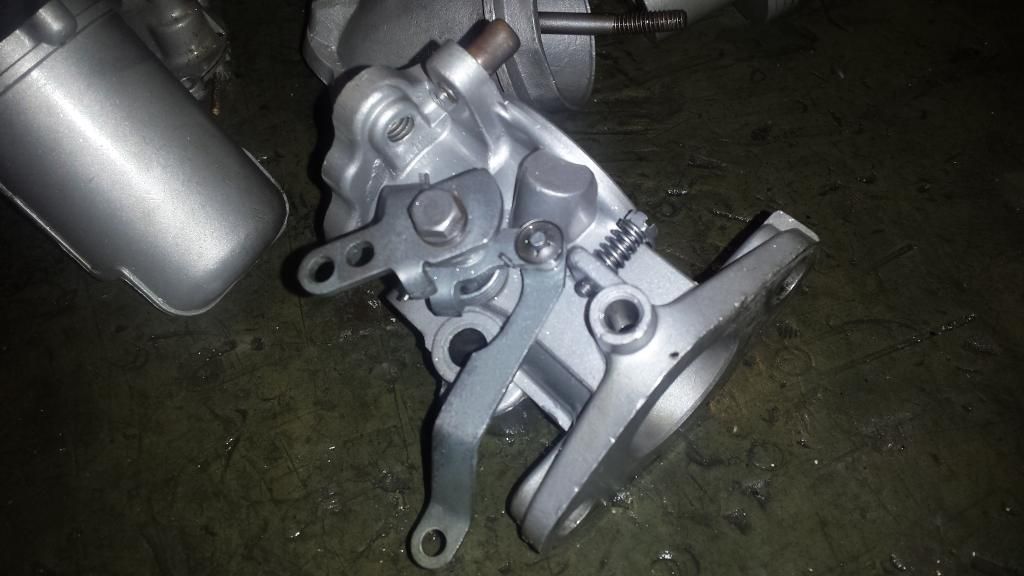

This is the carburetor AFTER I ran it through the turko bath

The zinc plated bits seem to be still zinc plated under all that garbage. A little more work in the float bowl yet to go.

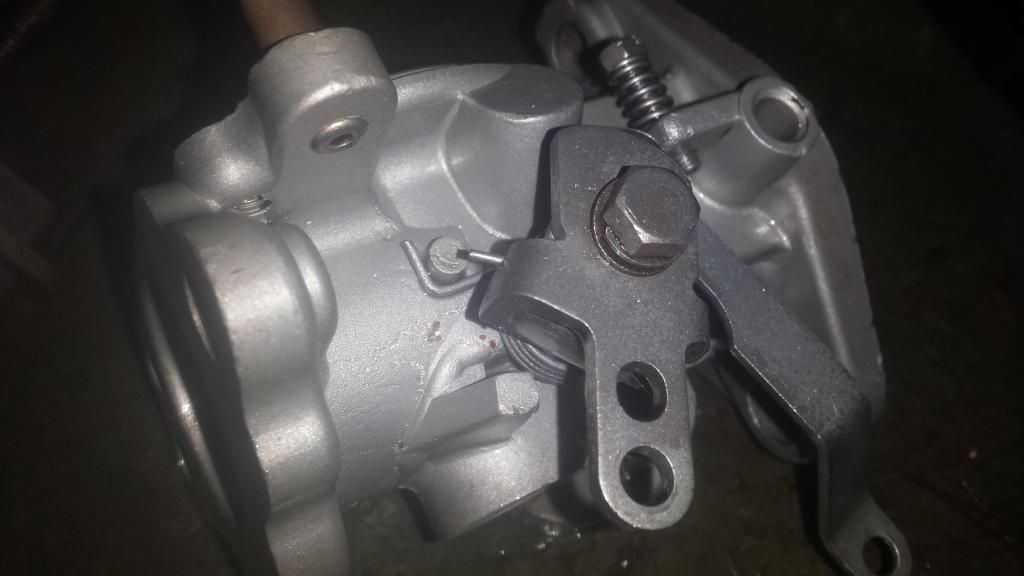

And after they had been through the glass bead blaster cabinet.