Hi All,

Finally got the project motor on the dyno.

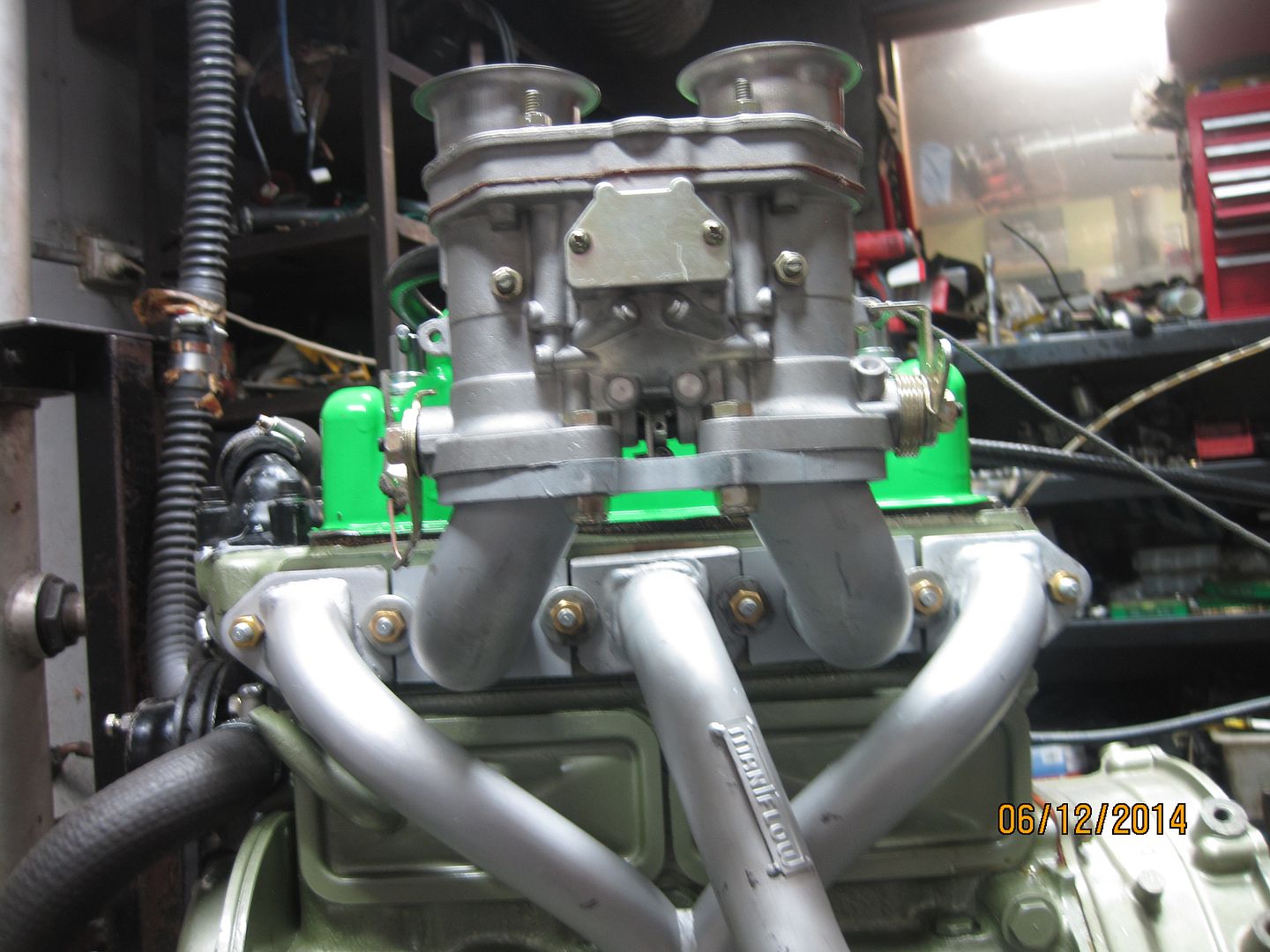

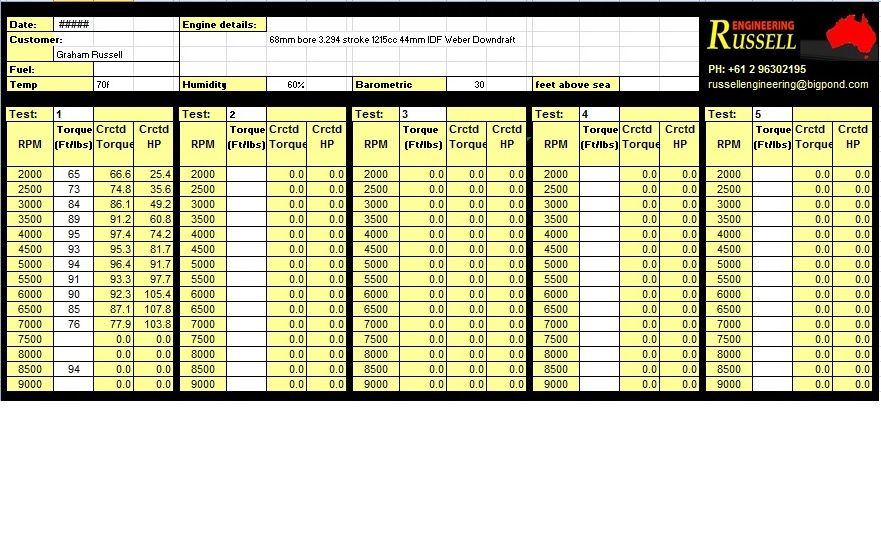

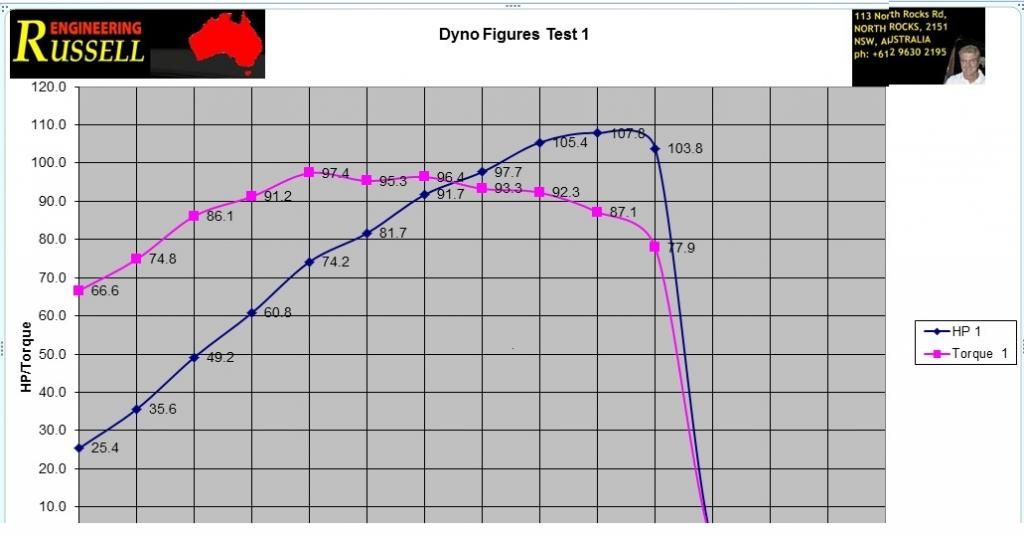

This is a 68mm bore 1100 motor with my new 266SS cam, and my new Downdraft IDF Weber and Manifold. The Cylinder head on this engine is a 202 head with 1.26" inlets and 1.07" exhausts. Other than cutting the seats using my radius seat cutter and relieving the chambers, the head is std. No grinding the ports or under the valves.

In Further testing, I'll grind the exhausts out and do the dyno readout again, then I'll do the inlets and do it all again to show the differences.

I am surprised with the way this new Cam works, this is a totally new 266 type grind and with a combination of the Carb, Manifold and Cam, it has come up with some amazing results. who needs a 1275.

I love small bores

All of this will all happen on my website, when Aaron types it up and show the entire build, including modifications to the block and head.

---------------------------------------

Here is a video showing how the followers and push rods should turn with they are ground correctly. The video is at about 1800 revs

http://vid1008.photobucket.com/albums/a ... I_0001.mp4

Graham Russell

PS: Thanks Aaron, for putting it on the dyno for me.