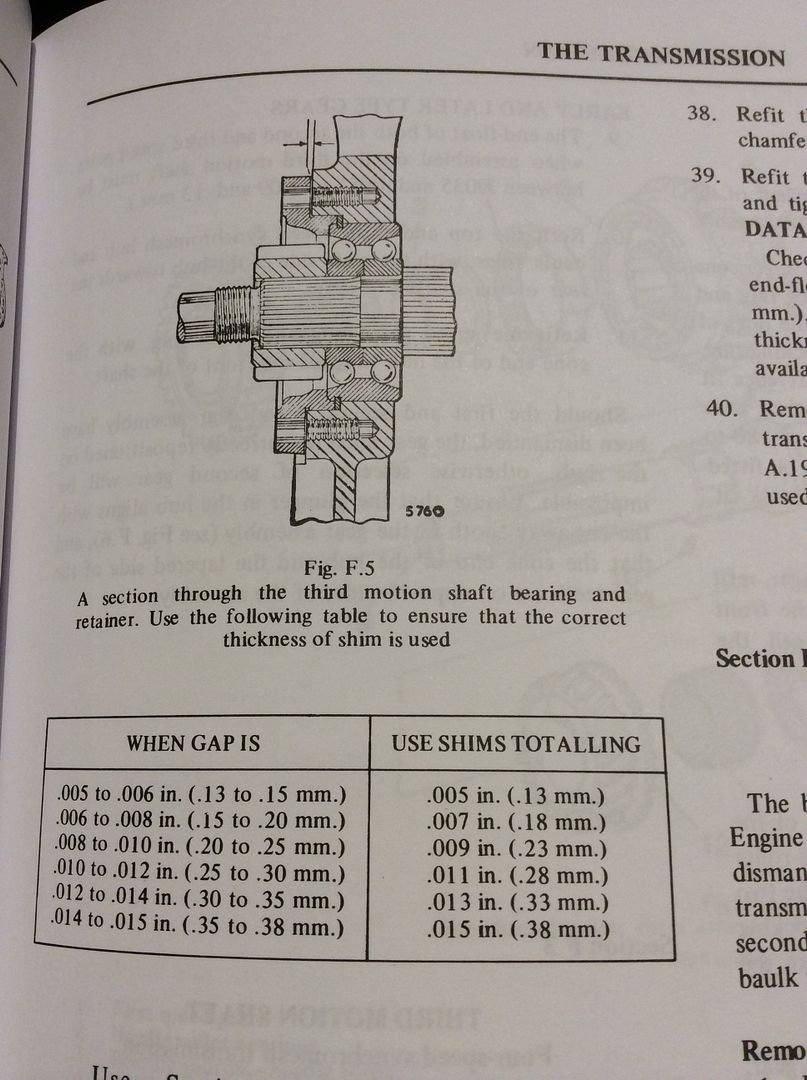

I presume your talking about the third motion shaft bearing retainer as per the image below.

I can see where it may be a close fit with a larger pinion.

I presume this retainer has a large section cut away where the crown wheel meshes with the pinion.