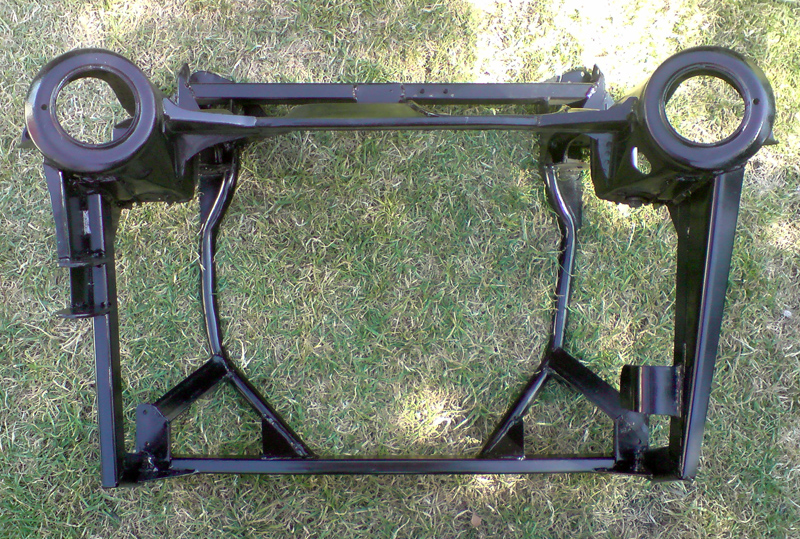

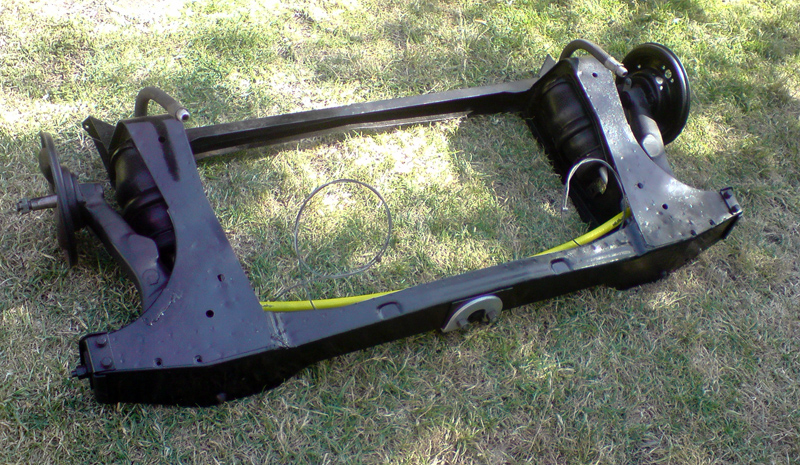

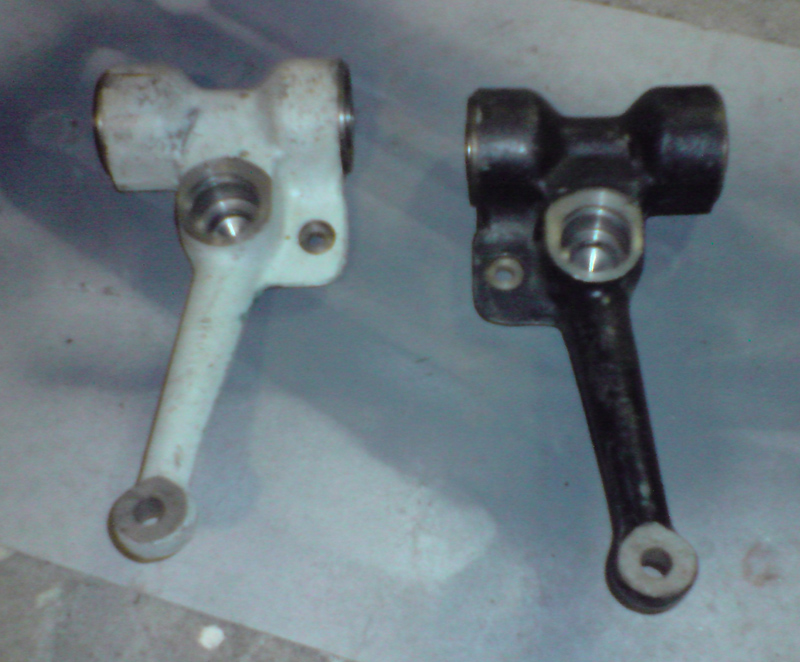

Right, have finally decided what to do for camber adjustment. Thanks to Mr Rosenthal for suggesting I revisit adjusting the top arm. The top arm pivot holes are a much easier proposition to make adjustable due to them being the same size to begin with, much easier to access and the design of the top arm pivot having a built in crush tube (well it's not but it will act as one). After assembling with some mock up tyres (how tough does this look!!) I deemed there to be enough clearance to the inner guard to go ahead. There is no clearance to the outer guard, but some big flares will fix that, I will also run a smaller tyre than this which will help.

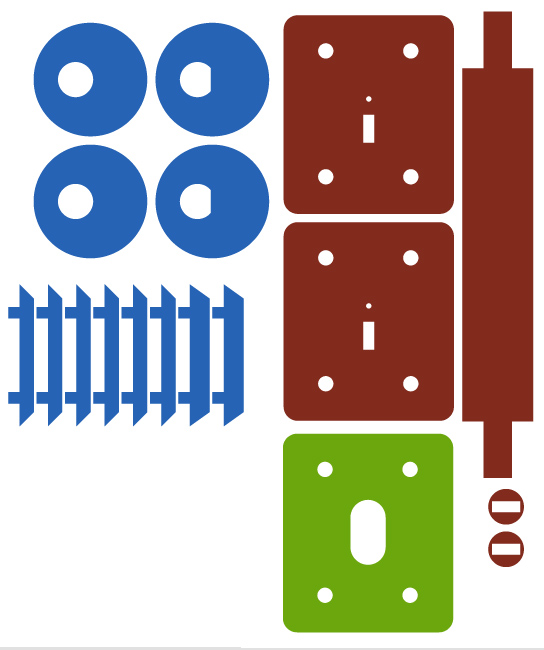

I drew up the desired eccentric washers in Illustrator (and my brother fixed them up in autocad) and have sent them to the waterjet cutters. Hopefully will have a kit of bits next week to finally finish the frame. I figured if I was getting them cu thten I had total freedom so I'd get everything I needed in one hit. You will see the blue washers which will go either end of the bolt. Welded near the head end and flat milled on bolt at the other end. The blue bridge bits will be the blocks either side that the washer push against to move the pivot bolt sideways. The brown bits are the kit to locate the drill guides so i can drill accurate holes for slotting and the bridge bits to go into. The green bit is a guide to file out the slots all the same. Hopefully it works, will post pics of the bits when I get them next week.

Cheers

Madmorrie