Hi Guys,

Well its time for another update, and yes it has been a long time between drinks!! I havent really been putting in the hours into El Gato as I would have liked - this thing called life gets in the way (most inconvenient

). Anyway, some things that were started two weeks ago have now been finished, namely the hydraulics and the fuel delivery.

I decided to take a couple of pics and update the thread now that they have been finalised. The Mobile Brake guy finished this afternoon in fact. He did a good job, it just took forever to get him to start - but once he did it was all finished in short order. I am steadily progressing towards the Muster, and having the car running, but time is ticking away and the job list is still huge. Anyway, all I can do is move forward and hope that it all gets done.

Anyway, to the photos..........

The picture of the engine bay showing the layouts of all the solid lines:

The brake booster (needs a bleed nipple):

Both master cylinders and the proportioning valve:

The flex line for the clutch slave - the original Toyota item had a few cracks starting to appear, so I chose to replace it just in case the line leaked and squirted brake fluid all over the newly painted engine bay. Nice blue braid to match the car colour:

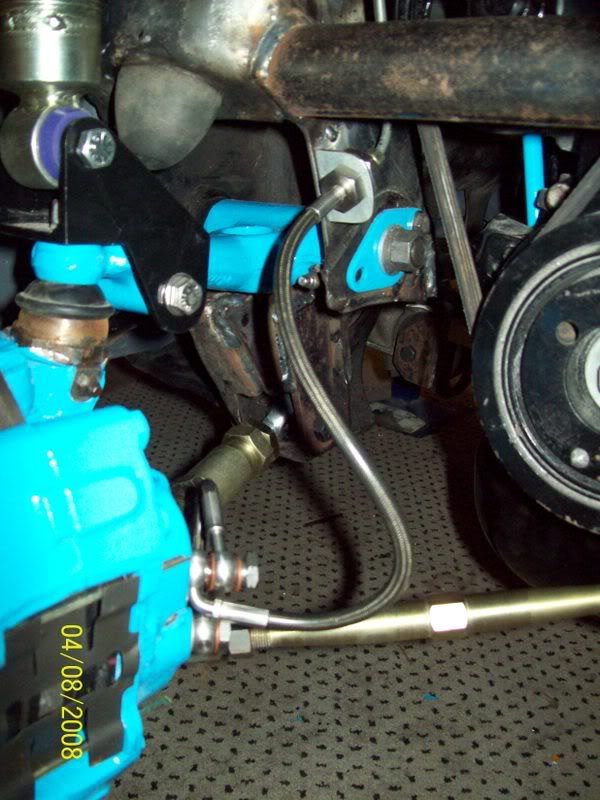

The rear flex lines on the swingarms have been replaced as they were the original Leyland items, and past their use-by date. Once again in blue braid:

The connection to the rear brakes - angled fittings and blue braid:

And finally the flex lines to the front calipers - sourced from the UK:

Now, on to the fuel delivery. I mounted the Sard Rising Rate Fuel Pressure Regulator (RRFPR) as close to the original position as I could get it, and still be able to view the pressure gauge. The incoming (feed) lines are 5/8" while the outgoing (return) lines are 1/4" :

The boot space. The in-tank pump feeds directly to the fuel filter. I chose to use a Delphi cartridge type filter as they last a lot longer and filter a lot finer particles. Also the glass bowl on the bottom allows you to drain the water that may appear in the fuel from time to time. The fuel filter then feeds the surge tank. The main pump, a Bosch 910, then feeds the fuel rail via 8mm bundy at a pressure of between 45-50 psi. The return line from the RRFPR feeds back through 6mm bundy and back into the surge. If the surge ever reaches overflow situation (extremely doubtful), it returns back into the main tank.

The in-tank pump/filter/sender unit is from an aussie Starlet. Unlike all the fittings of the surge tank (BSP), both pumps required metric fittings to be used so I had to get a couple of Speedflow items. The return line is obviously the smaller hose:

The tank is now securely mounted in place. The only thing left to fit is the filler hoses from the motorcycle-type fuel fillers. These hoses are 32mm:

Next week I am hoping to knock-off the shifter mechanism on the gearbox. The driveshafts have been sent away to be measured and machined (thanks Josh for the contact). Fingers crossed that they will arrive back in time. The new turbo has been ordered and should be here soon (temporarily out of stock), and thanks to Matt for that contact. Once the turbo arrives, it means the charge pipes, FMIC, turbo install, dump pipe and EM can be completed. That would only then leave the electrics, which can be done bit-by-bit at night (hopefully).

Cheers,

Tricky