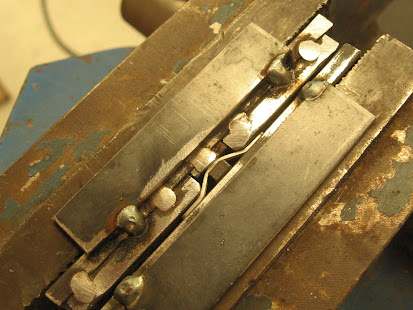

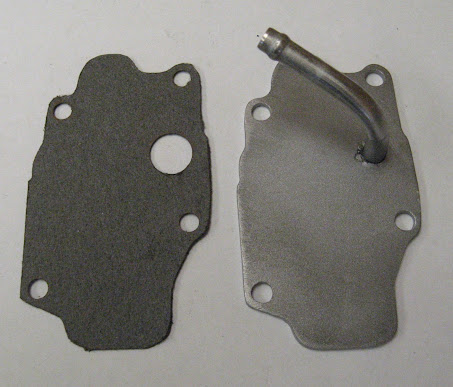

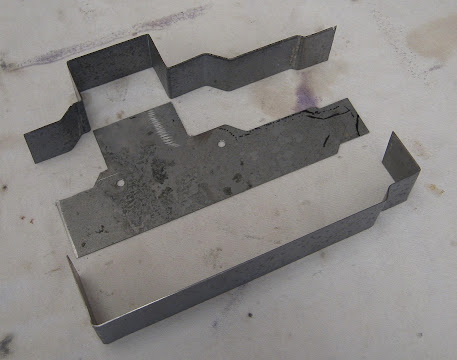

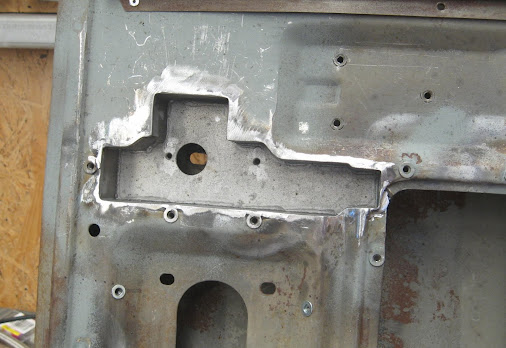

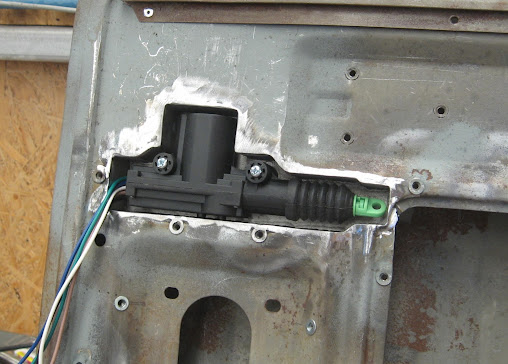

I decided to add to my To-Do list the feature of power door locks / central locking to the Mini and purchased a master and a slave actuator from my Jaycar. The actuators aren't large, but it was going to be a challenge to fit them in the Mini doors and keep them easily accessible in case they need to be replaced. I made an enclosure to house the actuator, made from a single backing plate and some hand bent pieces to create the sides, which were then welded together and then welded into the inner door skin just below the interior door handle.

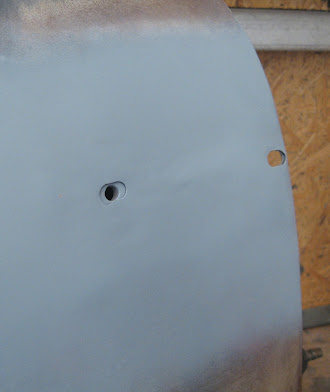

Note the larger hole to maintain access to the door hinge nut!

The enclosure has two captive M4 nuts for mounting the actuator

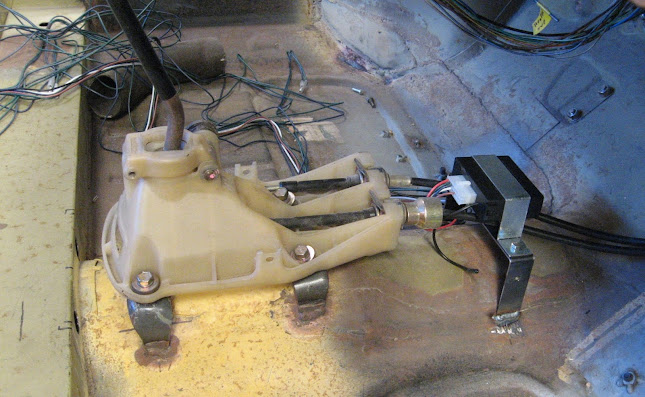

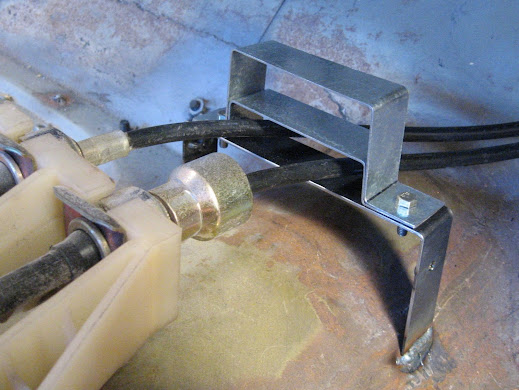

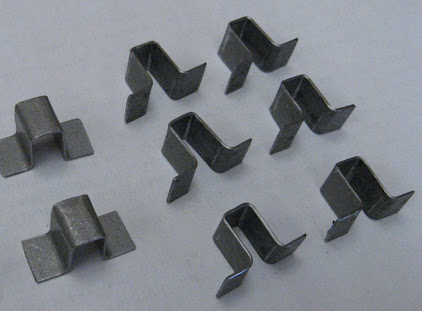

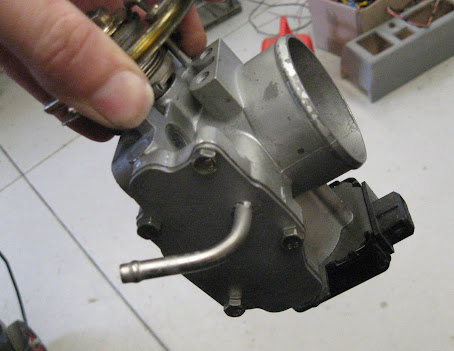

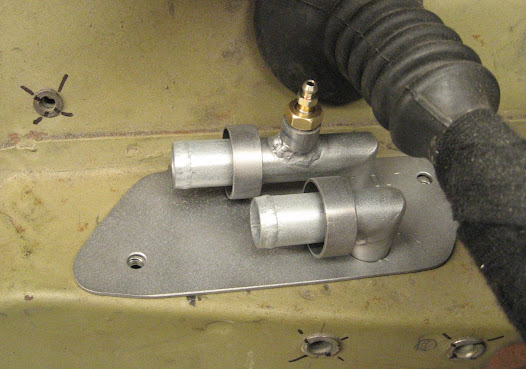

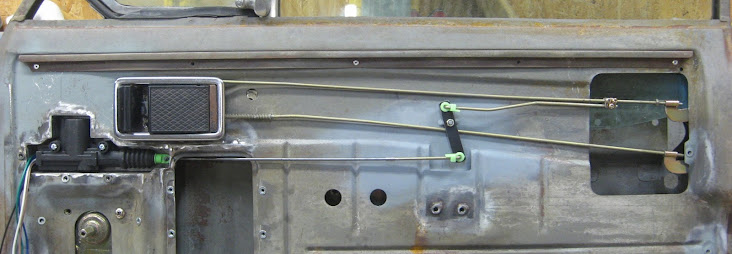

The generic rod that was supplied with the actuators (gold coloured rod in photo below) had a lot of free play within the green clip on the end of the actuator, so I made a replacement rod with a small collar that fits the actuator snugly and will use a nylon lock nut to secure it.

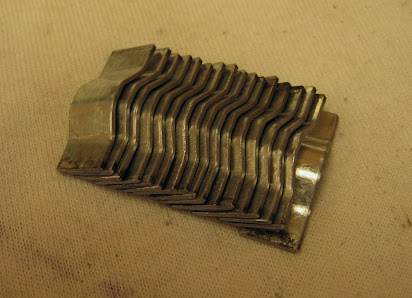

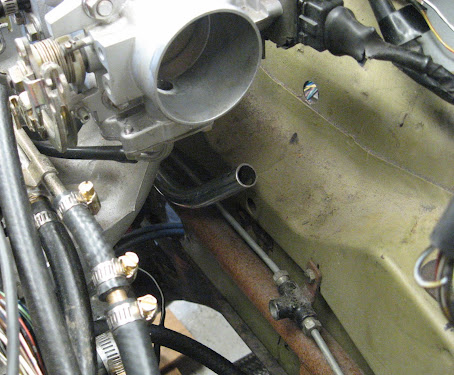

The main issue I faced was that the motion stroke of the actuators is 16mm, but the factory Mini door lock rod only requires approx 8mm to lock/unlock the door. This difference was solved by using a rocker arm with a 16mm movement on one side of the pivot and 8mm on the other side. I machined a standoff for this arm and welded it to the door skin, and also had to create a small recess in the inner door skin for clearance of the rocker arm.

After bending some rods for the mechanism, this was the final layout which easily fits under the custom fibreglass door card.

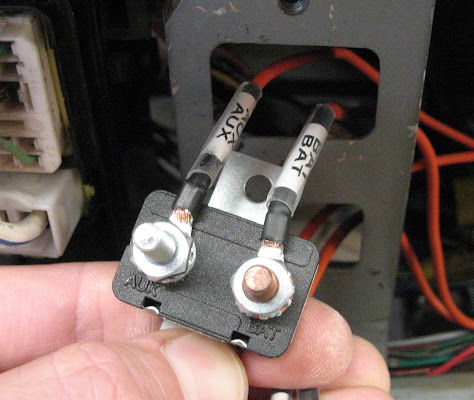

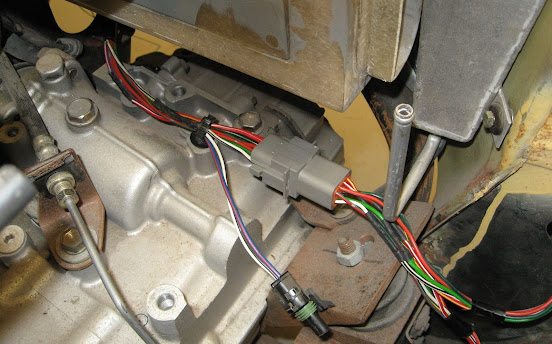

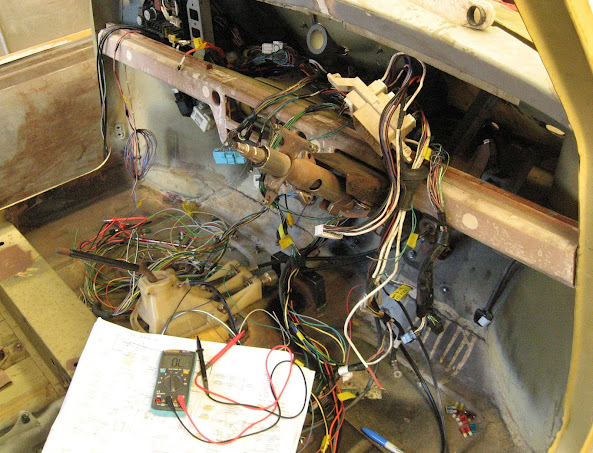

The master & slave actuators have standard wiring (5 wires on master, 2 wires on slave) and I'll be using a central locking controller (with remote keyfobs) to complete the central locking system install. The issue I face now is finding a neat way to route the NINE wires from the doors into the cabin (5x for actuator, 2x for power windows, 2x for speakers)