Thanks Tricky. Always good when a man of your talents likes what a pleb like me is doing. It certainly takes me long enough to churn out something 1/2 decent.

I managed to spend a few more hours in the garage today but it doesn't really show. I thought I had finished making a fly cutter but it turns out that it still needed more work done to it so I spent some time on that instead of working solely on the bracketry. Didn't take any progress photos today so I'll just cut straight through to an almost finished bit.

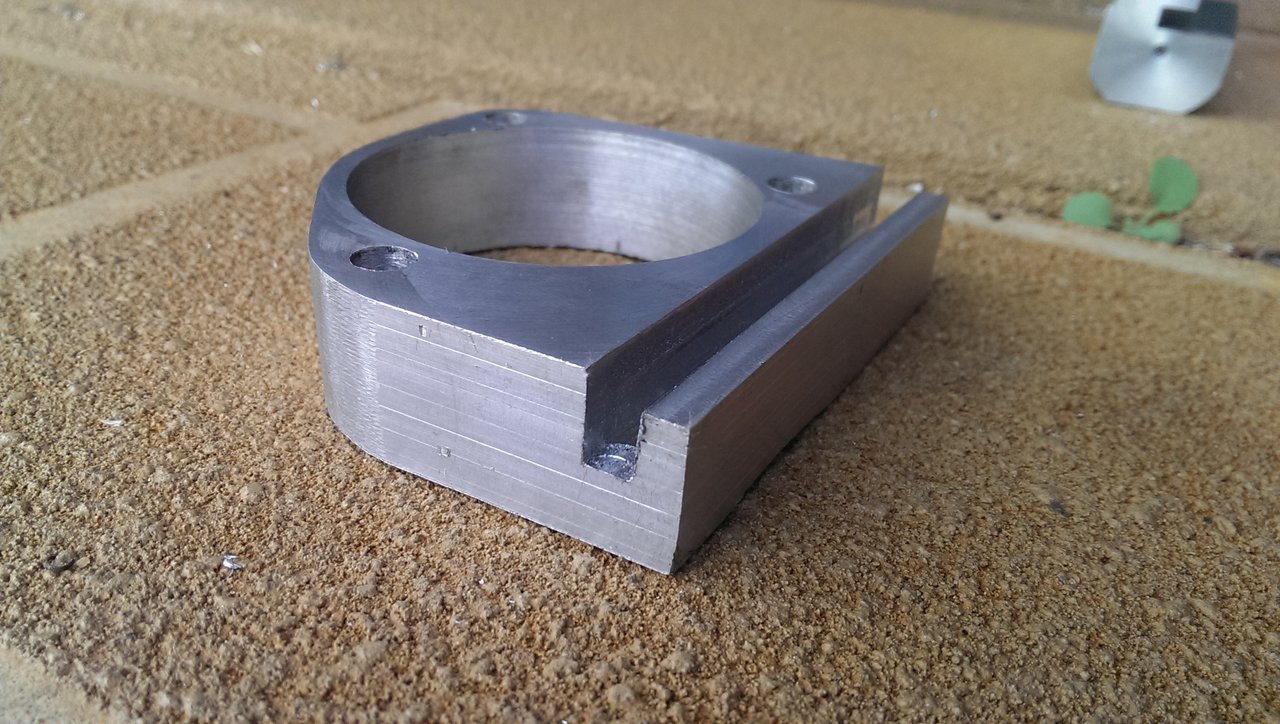

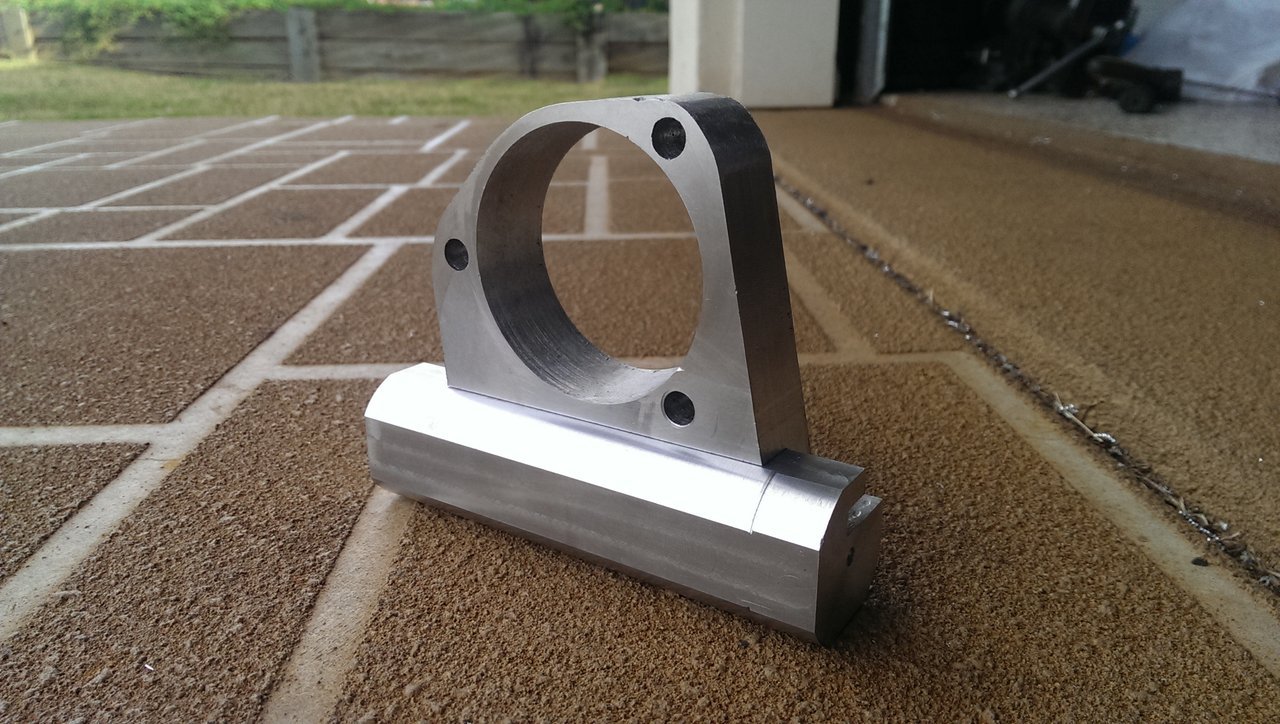

^Fly cut both sides and cut the 1/4" slot in the front

^Cleaned up the edges with an end mill. Used an end mill to do a bit on the corners but they are not concentric with the bolt holes so I just lined up how much of an angle it was on and adjusted the filing. Didn't turn out too bad and is even side to side.

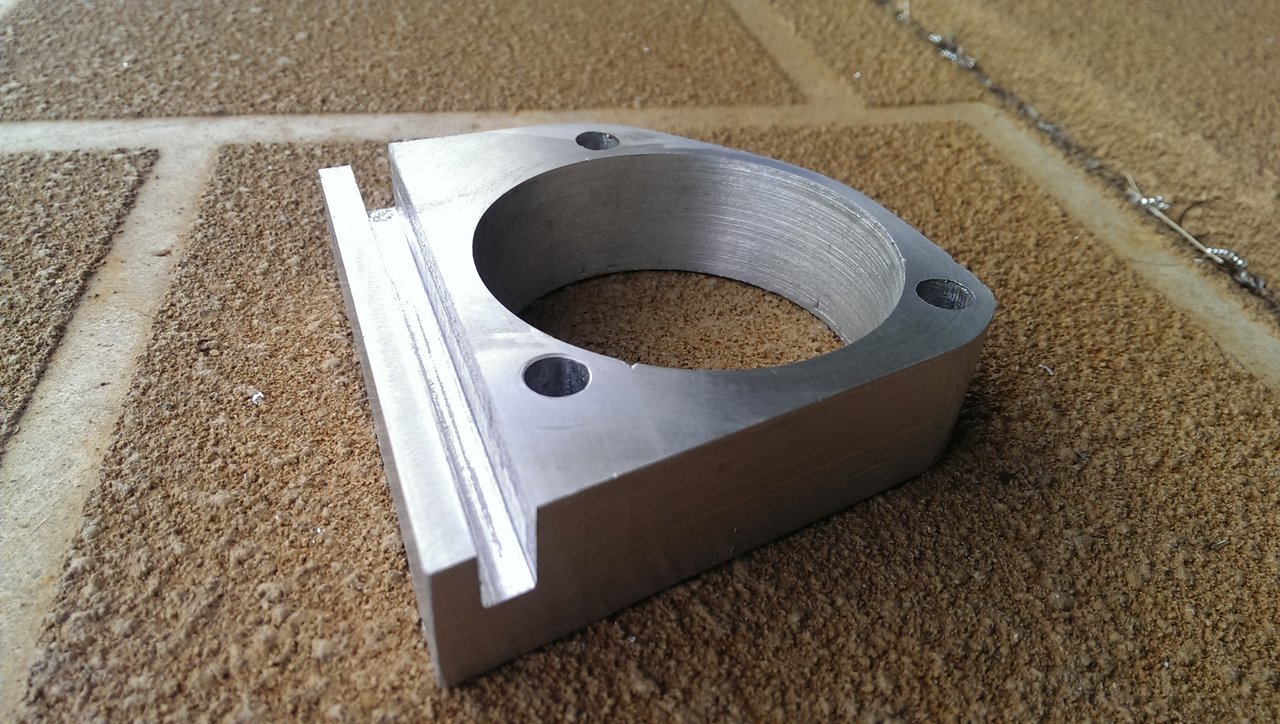

^Another view of the cut slot.

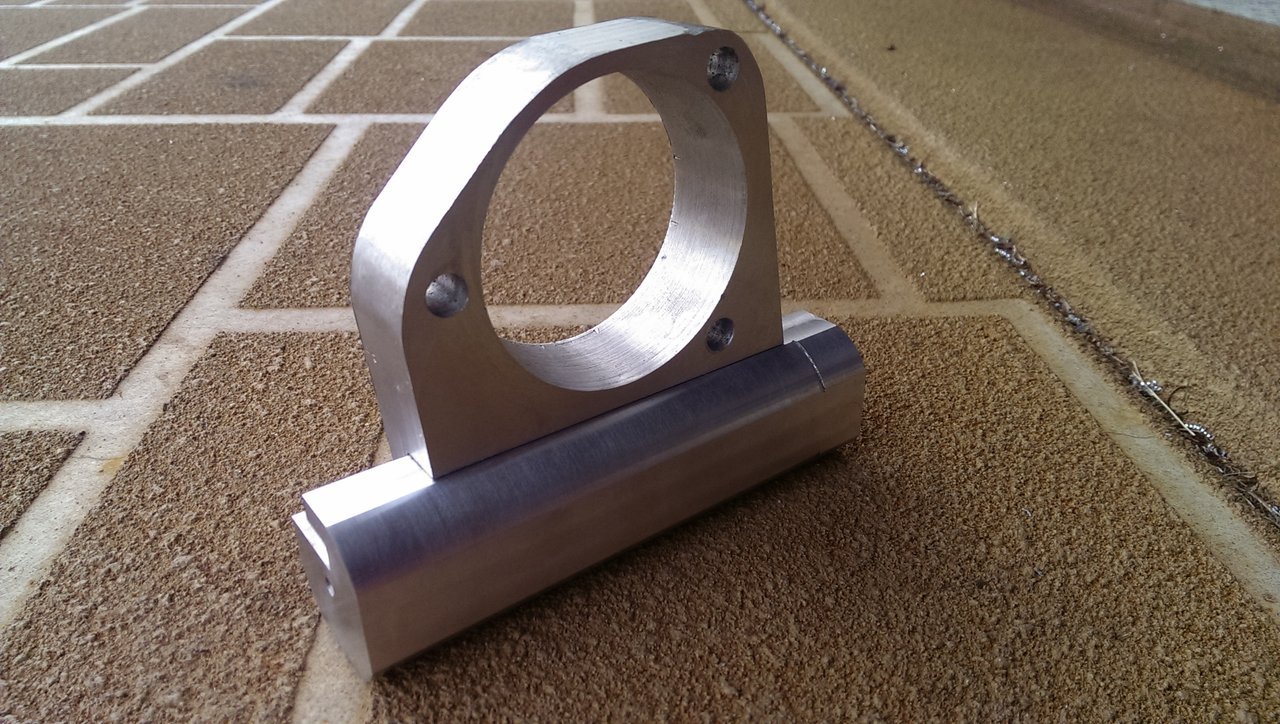

^Fitted together with the first piece I made. No slop in it either which is good!

^Fits nice. Still have to work out what to do with the ends after I attach the caliper and drill bolt holes etc. I have been thinking of making a ball turning attachment for my lathe so this might be the project that it is made for. Thoughts on turning a 1/2 sphere on each end?

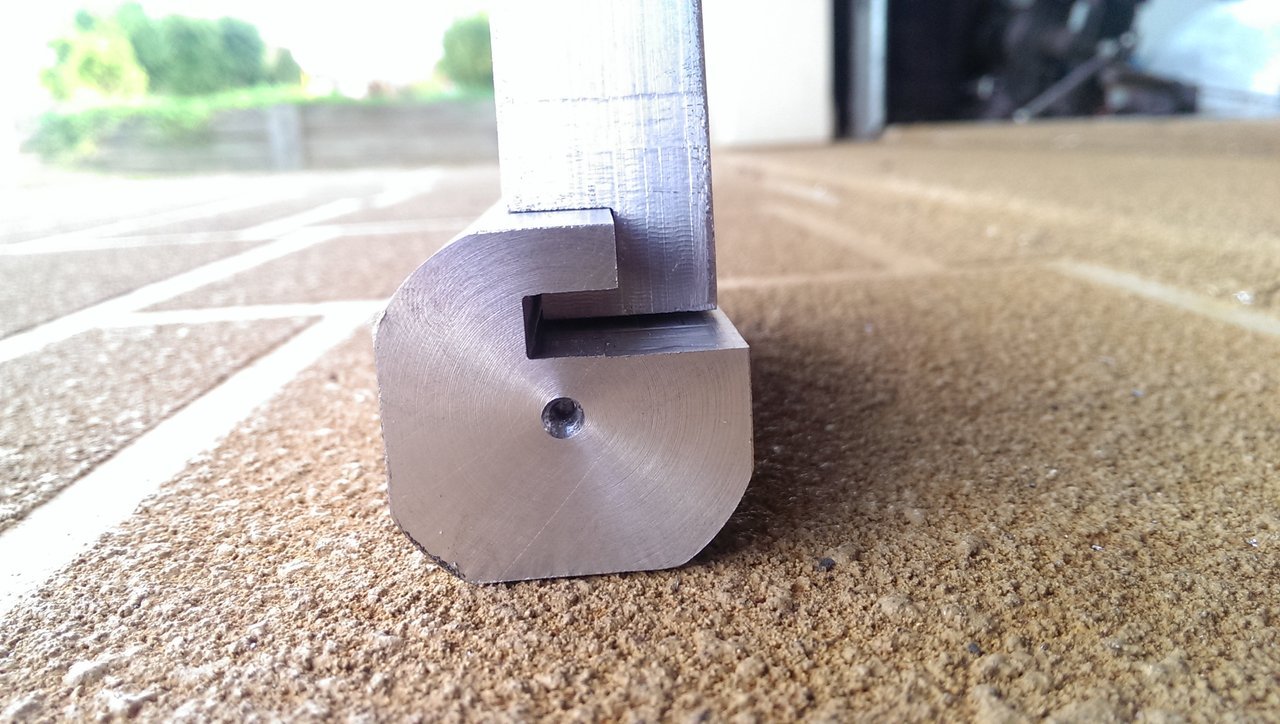

^Another shot assembled up.

I am now at the point where I need to work out what to with the bolt holes and attaching the caliper to the bracket. Need to do some more measuring of everything assembled up to make sure I don't take too much material off. When the car was down at Tricky's, he found that one side had a different measurement from the other but he couldn't see where (no obvious shunt, or differenced between the arm mountings etc). Need to work out what side it is but I think I might continue with making the passenger side upper bracket tomorrow if I'm lucky.