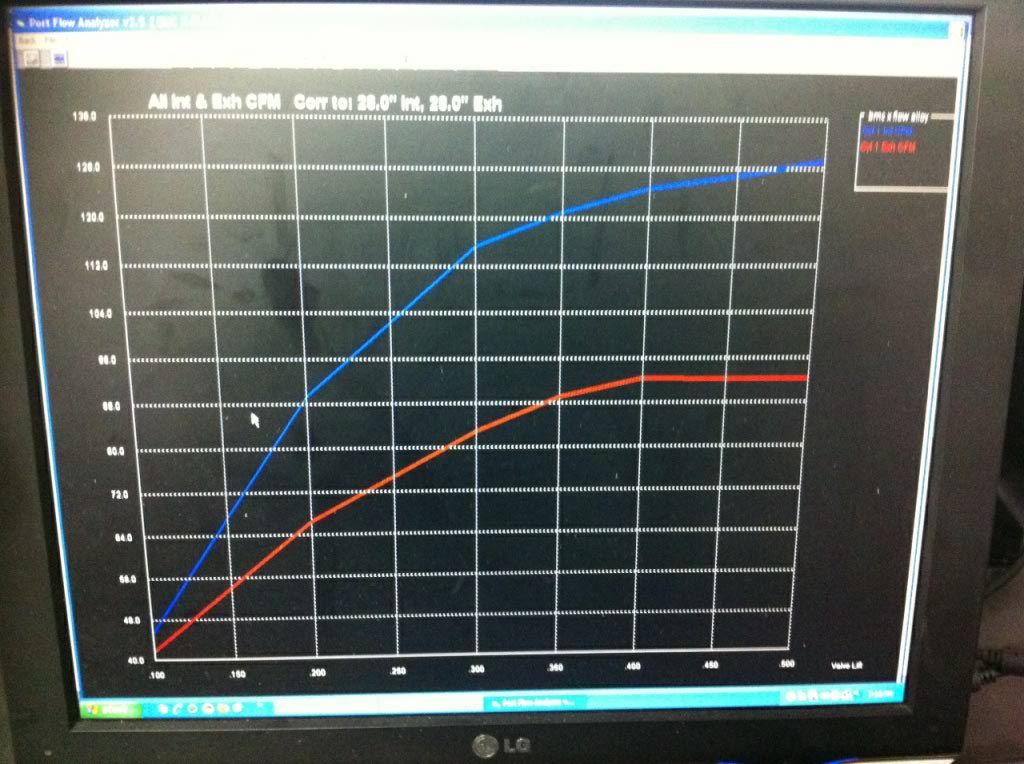

no we havn`t been able to make it flow 130plus at 200thou valve lift,,, or even 250thou valve lift,,,sorry,,, i`m not that good

you should be able to see the gains from this chart where it all happens, & most of it is above 300thou ,,, & just as the caps start smashing the top of the guides at 500thou

we have the use of a really cute air-speed probe so we can play around with adding metal & subtracting metal in different areas of the ports to see where we can gain & where it all falls apart...so (to me) it`s basically one of the best tools ever

it overlays the high/low & medium air speed areas onto a pretty 3D picture of the port for me

This info is all then all plotted against the cam profile you punch in , also all your info like valve sizes & engine capacity & such (Massive amount of info the computer demands) & you get a rough guide as to what it will be able to produce,,, & strangely enough (with most of the V8 engines anyways) it hits the nail on the head spot-on. (most times)

we are still toying/practicing with designs/data for the mini heads, 5,7port & twinkys so we are no experts as yet

but it`s fun & we are making chunks of ground compared to the way i used to do things