had a wee read of this bit by david ,and thought, woof ,,lets investigate ..

''On the subject of gear boxes, Asphalt included the pic of the diff,BUT!!!!

go to Quaife's website, look at the details of the mini diff and down load the drawings[PDF at bottom of the page] Then do the same for the honda civic diff[2 bearing sizes 40mm and 35mm -- funny but 35mm is 1.375" ] and compare the 3 diffs.

Then get onto flee bay and do a search on "Honda LSD" and you will find a brand new ATB diffs made by OBX in USA for around $350 [some times cheaper] The blokes racing the v-tec civics in USA are punching around 300 neddys thru them and they are bullet proof. Crown wheel PCD is the same as mini ATB, but has 10 --10mm x1 bolts instead of 6-- 3/8" UNF

Two complete brand new civic drive shafts here about $100. No more stick in a bucket fit CV joints and no more oil leaks ''

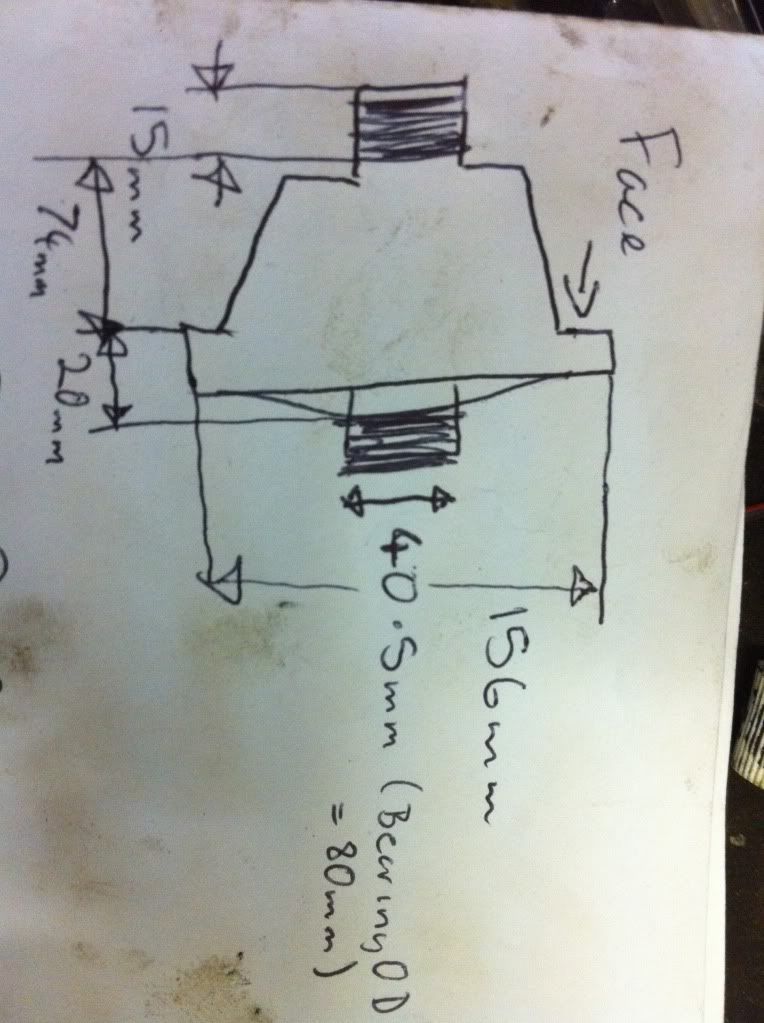

so got my chap denis (11.9s 1/4 mini )to measure a pg1 diff same sort of dimensions as ..

honda y1 and y2 cable and hydro trannys as found on all b-series hondas

these are the sizes ..

soooo this seems a fsair bit bigger than the a series ...am i measuring the wrong diff here like a numpty ??

regards

robert

_________________