My front wheels still wobble slightly in a 360 degrees radius when turned by hand and I'm now certain it's the bearings.

I've locked up the ball joints and steering track rod to check and it's definitely the bearings.

What I am not so sure of is how to use a dial indicator to check the end play.

I've basically stuck the magnetic end on the disc rotor and the needle on the end of the CV and rotated the rotor 360 degrees whilst "pulling" and "pushing".

I get two readings, one where the dial doesn't move which I've set to 0 and the other 6 thou (0 is at the start point and the 6 thou reading is when the rotor is turned 180 degrees).

These are minimum and maximum readings when the rotor is turned a complete 360 degrees whilst pushing and pulling.

My question then is this-does this mean the bearing end play is 6 thou in total so I need to machine off 7 thou off the spacer to allow for a 1 thou bearing preload?.

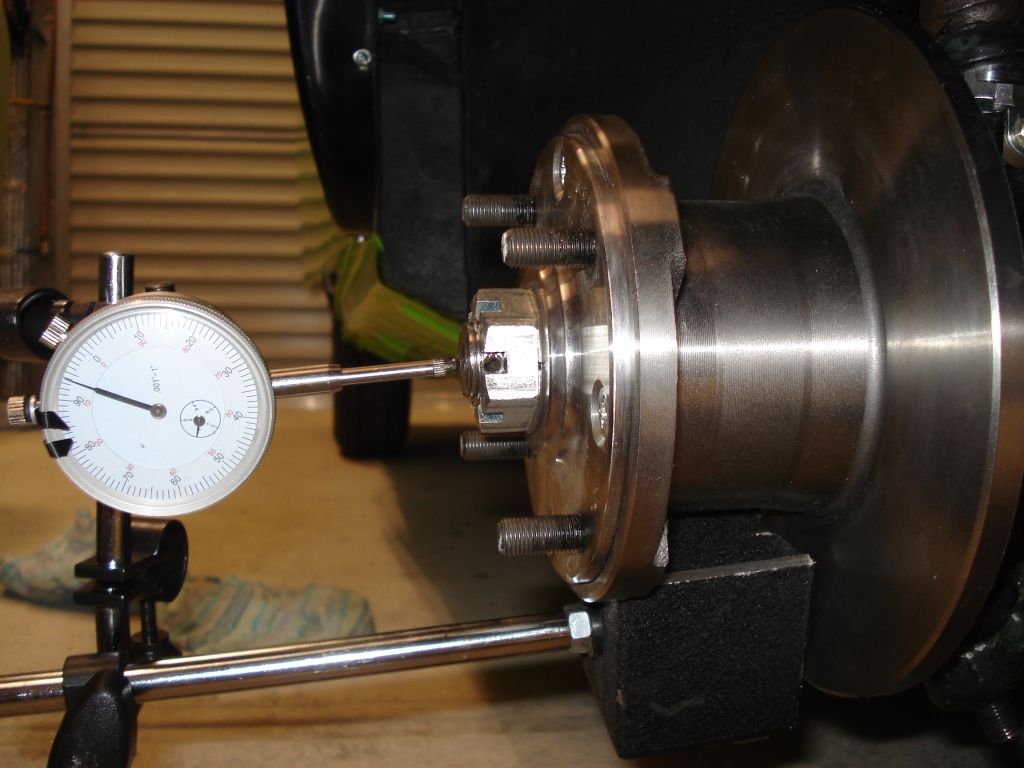

Here is a couple of photos of the situation:

Minimum reading (dial at the top) = 0

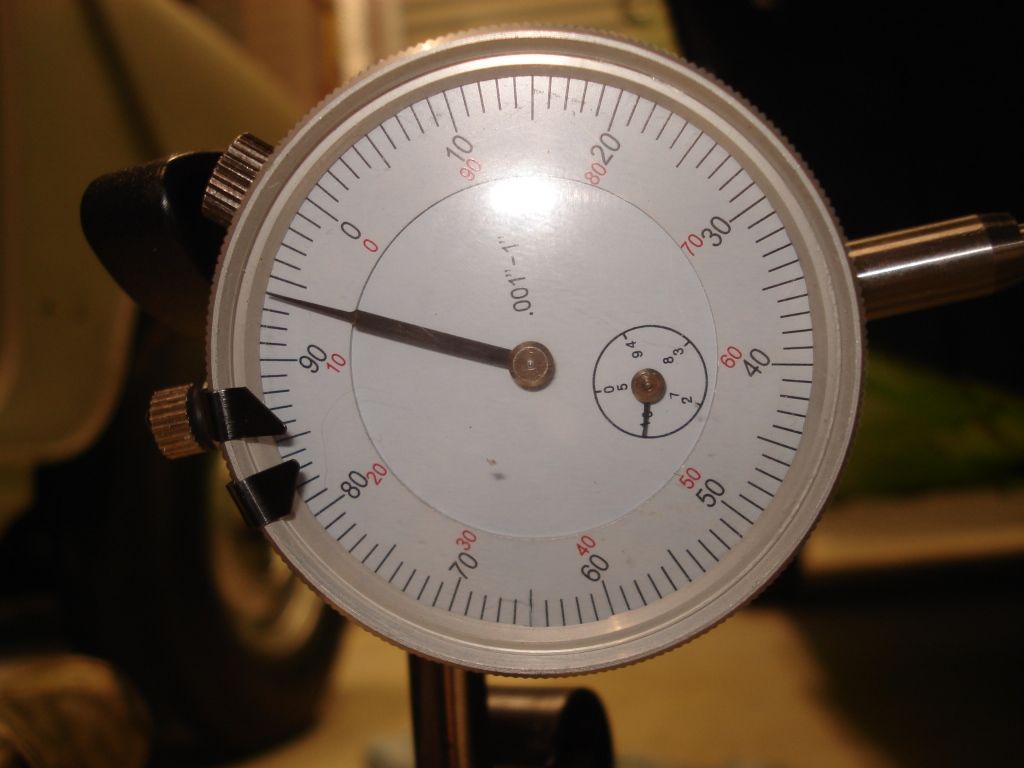

Maximum reading (when rotor is turned 180 degrees)= 6 thou

Maximum reading (when rotor is turned 180 degrees)= 6 thou

Any advice would be great as I don't want to stuff this up

Thanks

Dave