UPDATE 21st NOV

Well folks the numbers are in!

On Saturday i decided to put the engine back onto the dyno to try out a few intake manifold and exhaust setups to see where I can easily gain more HP.

This arose as Graham recently found out on the Project Small Bore motor (The Mini Experience Magazine motor) could not product the same results using a weber and a redline 3.5inch manifold. Graham said he tried lots of things including porting out the redline as much as he could to compensate for the shape and size that the redline is. He had eventually come to the conclusion that th redline was the key restriction as we all know that webers make alot of power and the exhaust manifold was the same Supa Pipes.

This sort of made me think about how much I was losing on a 113hp output which is slightly more than the Small Bore project.

So I decided to throw on Graham's 5inch manifold that has scored very highly on his flow bench in the past. In theory the longer intake will mean several things:

1) There will be more flow flow meaning more torque

2) The torque will be produced earlier (gets on the cam earlier) and the motor will hold onto the torque for longer

3) I will have to mod my firewall to accomodate the intake, sidedraft and a filter

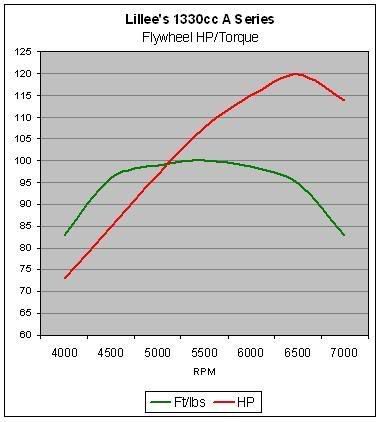

Well here are the numbers!!

119.7hp!!!

A few qucik Engine specs:

1330cc 1100S block

10.2 CR

RE13 cam

Maniflow medium bore LCB

RE5 inch intake manifold

36mm chokes

2" OD, 1 7/8" ID main pipe and straight through exhaust

So here's a few tid bits that some may find interesting:

- We tried to run 1 3/4 inch main pipe and 1 3/4 RC40 and lost (yes LOST) 10hp right through the whole rev range! We could not get the 1 3/4 pipes to work any better than around 107-112hp

- I am running no ram tubes, just Dr Mini's special tuning stub stacks

Did not try without anything at all but graham assures me that there is bugger all difference in them. This is good as space is already a premium at that end of things

- The minispares competition centre oil pickup LOSES 20psi oil pressure (from 80 to 60psi) when hard on the trottle. When you back off the trottle, it bounced back to 80psi. This is due soley to starvation at the pickup end and nothing else. There is simply not enough flow at the end of the pickup pipe. When i rebuild this engine I will piss that off in a hurry! or mod it to have a bigger mesh area

- I am running a total of 27 degrees max advance. She won't take anymore and does not need anymore.

- I am running a modified D4R83 pulsar dissy. I don't mean modified to accept a drive dog from a mini, BUT really modified as in change the advance curve to suit a mini. This is a BIG DEAL people so listen up! The advance curve on a pulsar dissy (either D4R83 or 85) have the wrong curve. They have far too much advance far too slowly. The result is that if you tune a stock pulsar dissy to have the correct curve at high revs, lets say 4000rpm, then you will lose up to 10ft/lbs of torque on the low end as the dissy is running way off down low. If you set it for the right advance down low, it will be way off at high revs which can be DISATEROUS. Be careful! I highly recommend if you are thinking about changing dissy to get your points dissy serviced with new points, rotor, cap, or get a pulsar one modified for the right curve.

Anyway, that's all for now. This week I will be frantically stripping Lillee to get a weber box welded and get this engine into my car so I can go for a drive!!! More updates later