I have reached a milestone which makes it feel like I'm driving a real car... the steering column

My approval from the Dept of Transport in Western Australia requires me to install a collapsible steering column so I've been forced to fit the Toyota Starlet column which is fine as I can ensure that the column is centred with the drivers seat and in an ergonomic position.

So this was a significant challenge to retrofit the Starlet column. First thing was that the lower uni joint on the Starlet did not fit the Mini Steering rack pinion and I eventually found a old G102 Daihatsu Charade had the same spline as the Mini

Dismantling the Starlet column was easy and involved the removal of a single circlip at the top of the column and gently knocking out the inner shaft. I didn't realise that the collapsible mechanism was so rudimentary. There are a two plastic shear pins (hard to see, but they are next to the paint dots in the photo below) that are inserted through the two parts of the inner column. Under a predetermined force, these pins will shear and allow the column to compress/collapse.

After offering up the column to the Mini dash, I found that the tilt adjust mechanism was complex and unwieldy so I decided to cut the mechanism off and set the column at a fixed angle

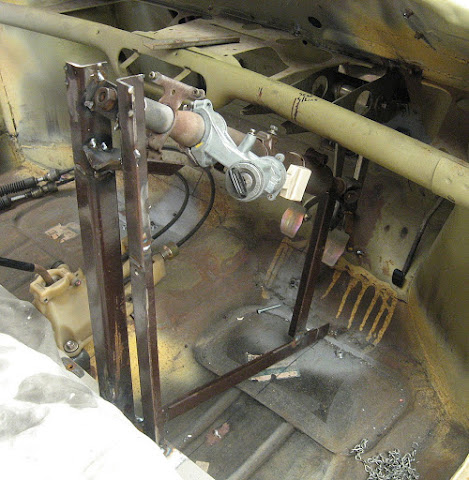

Using a combination of chains, clamps etc, it took a long time to finalise the position, height and angle of the steering wheel/column to find a comfortable driving position. I found that changing the angle of the column by just two degrees made a marked difference to the feel of the driving position. Once the position was found I welded together this structure from some scrap steel to hold the top and bottom of the column, leaving the middle area open to work around, then removed the temporary chains and clamps.

The main issue with the column mount design was that about half of the column projected out past the dash rail and would need a reasonable amount of support if the steering wheel is leaned on (eg whilst getting in & out of the car). After trialing a few ideas I decided on a braced triangular bracket that mounted to the lower dash rail - where the factory steering column was bolted to.

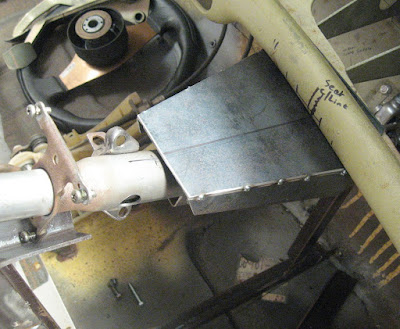

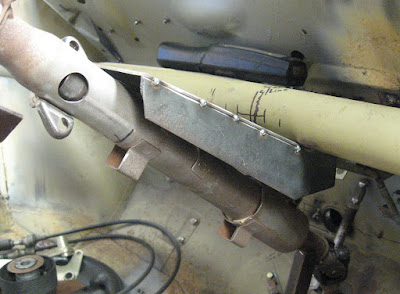

This support bracket shown above is made from 2.5mm steel and is bolted through the lower dash rail with three M8 bolts with the same style as the Mini plate (rusty one in the photo below). The support bracket sits under the dash rail and this plate sits above the dash rail.

The "arms" of the Mini brake/clutch bracket (pedal box) are clamped to the lower dash rail by the factory steering column bracket, so this new bracket had to support the Starlet steering column AND the Mini brake/clutch bracket. This is the reason for the asymmetrical shape of the new column bracket - the left hand side of the bracket has to be slightly wider to go around the brake/clutch bracket.

_________________

-Alan

I blame my dad for my love of minis. I think I was conceived in the back seat of one

I also blame my Dad for me being 6' 1" - not really the optimum height for driving a Mini.