I've just been for a quick fang in my mini for the first time since April last year!

I took it out to Syd's (Tspeed Jem) place to pop out the engine and install a central oil pickup so that I could have more fun at the roundabouts. No problem. We decided to install a new layshaft and bearings while we were at it. Once the engine was back in the car we tried to put the car into gear and discovered that we had nothing but reverse (not as useful as you'd think).

One of the other club members suggested that we may have used a slightly long bolt when we reinstalled the bearing retainer. So out came the engine for the second time. Popped of one of the side covers on the gearbox and sure enough that was exactly what the problem was. We put it all back together and back in the car. This time we had all the gears but when we started it up, there was an obvious leak at the manifold and the car wouldn't run. One of the stud holes was stripped and wouldn't hold tight. So off came the head and we ordered a helicoil kit from fleabay. When that came, we helicoiled the hold and one of the other ones which was looking a little dodgy.

It was then time to clean up the block face and put the head back on. That's when Syd noticed a sizable chuck missing from the edge of piston 4. Bugger, time for a long overdue engine rebuild. We pulled out the engine, stripped it and took it down to Berco for machining. Luckily the bore was undamaged to we just had it bored out a further 10 thou to 30 thou. I bought a new set of pistons and bearings and had GR grind an RE83 cam. We then reassembled everything, dialled in the cam and put it back in the car. I went for some dished pistons as the old flat-top Mahles had the compression up at over 13:1. Probably the cause of the detonation which killed the old piston. The compression should now be more like 10.5:1.

Next step was to run in the cam. No problem, fired it up and ran it at 3,000 rpm for about 20 minutes. Syd then put his foot on the clutch to move the car out of the garage and the engine promptly stopped. Bugger again. To cut a long story short, we had managed to install half the thrust washers in backwards. I ordered a new set of thrust washers and we put them in and put everything back together and back in the car. At the same time, I had read a post on here about putting the piston rings in the right way up. We pulled each of the pistons back out and discovered that I had managed to put 7 or the 8 rings in upside down.

We took the car for a quick test run and it wasn't too bad at low revs but the spark seemed to break down when it was given a bit. That's when Syd noticed that the coil was wired up backwards. Once this was rectified, the car started to run beautifully.

I drove it back from Syd's yesterday and went for a running-in fang this morning. The RE83 seems to pull very strongly and I'm very happy with it so far. I'll try to get out for a decent run in the next couple of days.

I've made a lot of mistakes in this whole process but learnt a hell of a lot as well.

Heaps of thanks especially to Syd (Tspeed Jem) for his time and garage and also to Santino and Scott.

Cheers,

Simon

Number 4 piston. You can see the marks from the broken bits of piston. It must have exited the cylinder fairly quickly as there aren't too many marks.

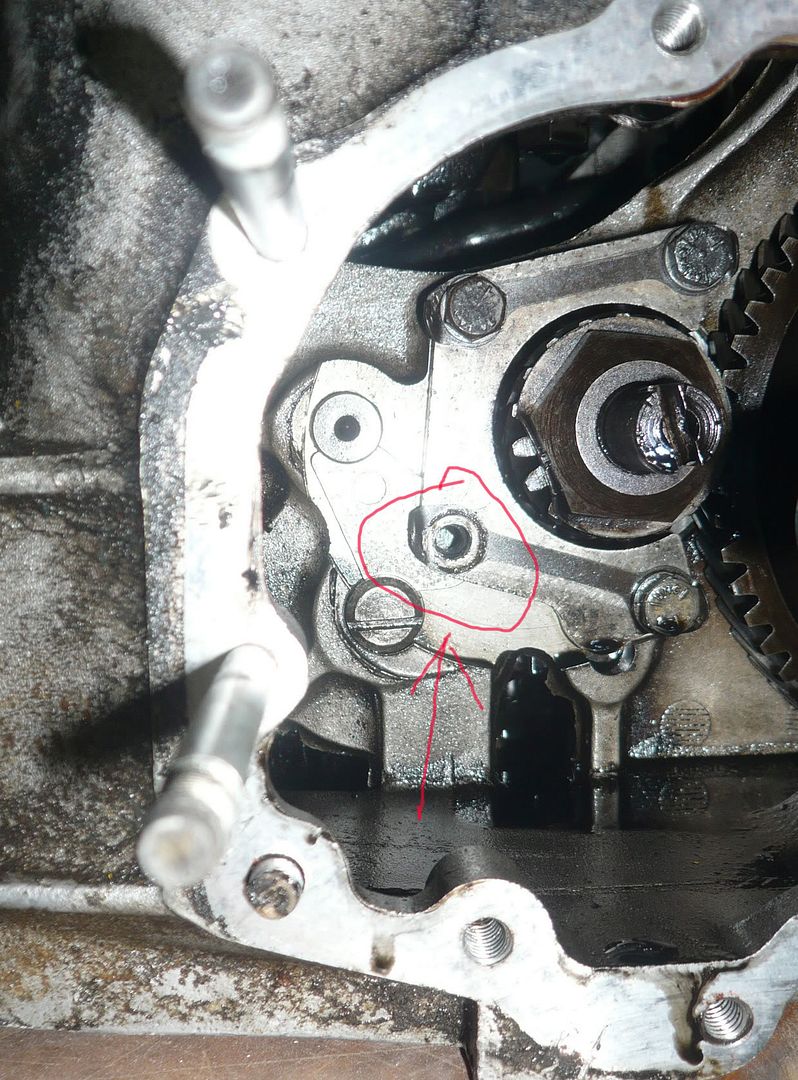

Where you shouldn't stick a long bolt