Hi all!

I am about to embark on rebuilding an A series engine for Lillee. Since I am a relative newbie at this (frist engine rebuild) I thought I might start a thread as it may be interesting for you all who wondered what a rebuild involves and maybe get some value off my own experiences.

HISTORY: Before I bought Lillee 3 years ago, I literally knew nothing about cars beyond doing an oilchange. It has been my dream to learn to fool around with cars and I've always wanted a mini! So if you know nothing at all, have no fear! just bight the bullet, read books and ask questions! If I can do it, so can you

. Well I have also had the luck of tapping into Dr Mini's endless knowledge. The guy truly has forgotten more than I will ever learn about Minis!

I do have a relatively limitted budget as I have to conform to the increasingly popular Marriage Budget

(All those who are married would understand!

)

AIM: Around 100bhp big bore motor with lots of torque and reliability on a remote box. It will be road car first and foremost but since I have a second, more mundane car to drive around I can afford to go abit on the silly side

. Fuel consumption is not a concern, neither is noise, so I will be building mainly for performance and power without compromising on reliability.

The big thing is I want to do as much of it myself as possible. Of course I am extremely lucky to have the very generous help of Dr Mini and will be taking alot of advice from the good Doctor. I also will be doing alot of work under the watchful eye and guidance of none other than Graham Russel. I am hoping between Graham and Kevin I can learn all I need to know to put together a highly modified, well built engine!

The current 1152cc in Lillee. Aint she a beauty

That there's a 45 Dellorto. Once you've gone sidedraft you can never turn back!

THE STORY SO FAR: I have collected many parts over the past 3 years and have in my posession 2 1100S motors to draw parts from. 1 Metro head, 1 normal 12G940. I will be using a late 1100S block that is currently 1275 (one with a hole between 2 and 3). Most of the parts will be from the 1100S with the exception of a Trigger belt drive kit, some special tuning nissan parts and a few other Toyota goodies.

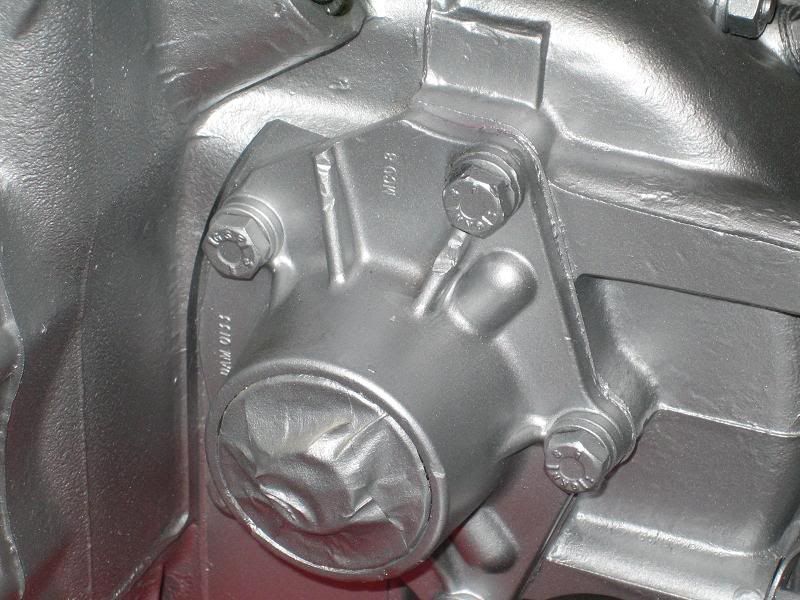

Kev and I have built a 12G1128 remote box from the ground up. It now has Mk 2 S ratios as I purchases a Mk2 S first motion and laygear from Minispares when I was there last year. Just touching on the gearbox: a whole kit has been through the box with all new bearings, a DR MINI Special Tuning rebushed mainshaft, MG heritage layshaft and a centre oil pickup. The diff has new heavy duty pin and new planet gears. The diff has also had DR MINI Special Tuning mods to accept an A+ diff thrust washers (with that little tab so the planet gear doesn't grab it and spin it). All new gaskets have been put in and it is now painted in silver engine enamel and sitting on my bench in a dust free wrap

Picture of my Mk2 S box with pot joints

Dr Mini Special Tuning modified pot joint side covers

(hint chunk off the top)

YESTERDAY: After procrastinating for several months I have finally started on the rebuild. The original plan was to bore my virgin 1275 block to 1330. This way it will have 1360 and 1380 left go and still have CC's under my belt. Graham wants me to go 1360 straight for more power (no substitute for CCs!) but he has conceded that it is a waste of a perfectly good block. I have purchased a set of Hypertech Pistons +060" (1330) from Minisport SA and they come with a new set of Hastings Rings.

I took the block, spider drive cam, crank, pistons, S rods and flywheel with backplate to Graham today. The block has been totally dismantled including the oil gallery plugs tapped out. Kev has drilled and tapped 10th and 11th head studs and decked the block to clean it up and make sure it is flat. Graham threw it into the hot tank for a few minutes and it came out sparkling. Well almost. I hit it with air and rust flakes flew out of the water jacket!

. I think we may need to send it to get it chemically stripped... Graham says that stuff will just clog up my radiator.

I would also like to file down the burrs of the hole in between 2 and 3. Apparently cracks can develop here as per Vizard. Graham says "meh you can do that if you want" so I will

Graham found that the bore on Number 3 cylinder has big chunks out of the side wall! It's had some big bang at some stage apparently. Gaham hopes that .060" rebore is enough to clean up the cylinders. If not I will have to go to 73mm pistons (1360) and use a set of Graham's very sexy looking pistons

I used this cool hydraulic press to push each pin out of the old pistons to disconnect the rods from the old stock pistons. Way cool

Old pistons

See the slot that runs horizontally? Graham says this is why they break when revved hard. The slot is HUGE, like half the diameter of the piston on both sides

I then started balancing my S rods myself (under the guidance of Graham) on the belt sander. I've never done this before so it was quite fun! He gave me some pointers and off I went! After about 2 hours I now know how much effort goes into this type of work!!! I compare my 2 hours of work to what Graham has done for a Nb racer and I am shocked!

The aim is to make them all the same weight. The theory is if engine internals are light, the engine can spin more freely and there is less load. Vizard talks about this in his book

Graham also took alot off the sides of the big ends and I have rounded off the small end and taken most off the sides of the rod. They have come up quite bling even if I do say so myself

On these I will use Ford rod bolts that will require mofication. Kev says this is a good mod as the Ford bolts are 16 for about the same price (or less!) as 8 S ones and are very good. Hey if they can hold a Ford V8 200+hp engine together why not a mini with 100hp

During the week Graham will have a look at my 1100S small journal EN16 cross drilled crank. It is currently .010" under on both the big ends and mains, but does look good enough to use. Graham will just balance the crank, I won't be doing any fancy wedging work which Kev feels is not necessary for a road car (although a nice to have). Maybe next time...

He will also grind my spider drive cam into the popular RE13 cam grind. I have been in many cars with this cam and I am sold. It will be a good power producing cam and will pull from usuably low rev ranges.

THE NEXT EPISODE: Will have to look into the block cleaning. If the bore turns out ok, then Graham will fit the pistons and I will buy parts such as Isky style cam followers, ACL Duraglide bearings for the crank, and Hopefully I can just reuse the cam bearings already in the block. If crank turns out ok then I can start putting it together!

Tune in next time! Thanks for reading! Hope it didn't bore you to death. I will add more pics next week of the progress.