OK, update time.

The day started well, with assembly of the CVs and driveshafts and fitment to the car. Can't remember where I picked up this trick, but it's a good'un -- a length of thin plastic pipe (the nozzle of an old can of WD40) inserted into the CV boot, which allows the boot to 'breathe'. When the brakes get hot, that heat is transferred to the CV and the air in the boot expands. If it's sealed, the boot expands as well and can rub against the upright, wearing a hole. This bit of pipe solves that

With the drive shafts fitted, we could fit the uprights:

.. and with the uprights on, the discs and drive flanges were next (although not yet torqued):

This is all going very well. Next up, fit a caliper and double-check that we have clearance to the wheel.

Yep, it's all good. ALL good

Um, wait a minute. Mini Spares said something about some undefined clearance problem between the calipers and adjustable lower arms. Better figure out what that's all about. With the car in the air and the suspension at full throw, there's a clearance problem alright. Only about 2/3rds lock is available before the caliper touches the big, square section on the caster bar:

The way I see it, I'm not likely to be asking for full steering lock while I'm getting air, so this is unlikely to be a major problem

From the looks of it, it appeared that with the suspension at normal ride height the caliper would clear the arm, and it turns out that this is true:

At full lock, there's still a few millimetres between the caliper and the caster bar, so we're safe. It's a bit hard to make out from this shot, but a miss is as good as.

Well, so far, so good. We got this far in only a couple of hours, so it looked like we'd have the car on the road in the afternoon. Best laid plans, and all...

Decided the next thing to do would be to get the brakes bled. It was about now that I realised I'd fitted the calipers without attaching the brake hoses. Why, oh why isn't there a union fitted to the end of the hoses!? The calipers had to come off in order to get the hoses attached, but hey, no biggie. While we were there, we got the pads fitted up (after grinding a few millimetres of the corners of the backing plates of the inside pads so they clear the calipers).. looking good

Calipers back on, it was time to bleed. I picked up a Gunson's Eezibleed with the Mini Spares order, so figured bleeding would be a snap. Not so, unfortunately -- as I suspected, the kit doesn't come with a master cylinder cap suitable for the large Lockheed plastic reservoir. As I don't have a spare cap, I ended up modifying my cap to allow the Eezibleed to fit. As a result, I now have a master cylinder cap with a bolt in it, sealing up the hole we made

No photo, unfortunately.

So anyway, back to bleeding. With the system nearly completely evacuated after the disassembly, the rears were the best place to start. That meant getting the rear wheels off, which meant getting the front wheels on and the car off the axle stands. While fitting up one of the front wheels, we discovered that one of the wheel studs had not been press fitted very well and spun in its seat, stripping its splines

Nobody nearby could supply me with a new stud, so it got Loctite'd in. Here's hoping it holds

From here, things seemed to take a bit of a downhill turn. Bleeding the brakes turned out to be a #$@* of a job. The Eezibleed probably works pretty well with the master cylinders for which it has caps, but I couldn't get a good seal with mine which meant we had brake fluid leaking all over the place. Eventually though, we got all (most?) of the air out of the system and attempted to get a pedal.

Attempted, that is.

No go. The pedal goes pretty much all the way to the floor on the first stroke, and after a few pumps comes up to about half way. Once there, pressure can be held and the brakes seem to work pretty well, but release your foot and it's back to square one. There doesn't seem to be any air in the system, we've put at least a litre of fluid through and there's very little, if any air being expelled.

I'm at a bit of a loss as to why we can't get a pedal. With drums all round, the pedal was high and hard, but now..

Anyone have any suggestions?

My suspicion is that the 4-piston calipers require a larger volume of fluid moved before the pads engage the discs, and the drum-type master cylinder isn't moving enough. Pumping the pedal quickly delivers enough fluid to get a pedal, and it's all returned to the master cylinder when you let the pedal go. Does that sound reasonable?

If so, what's the best master cylinder to get?

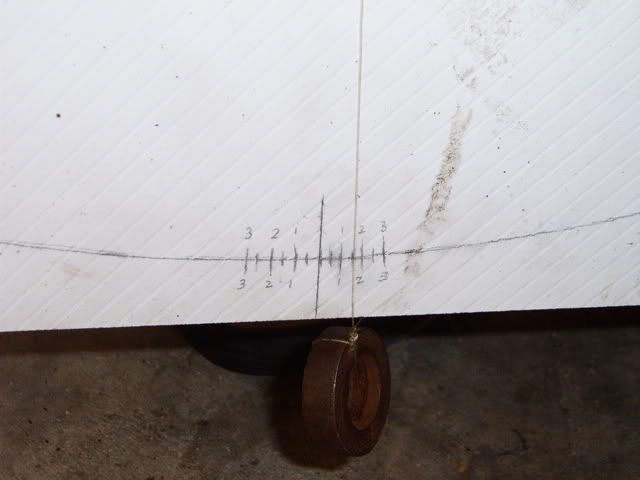

Anyway, with on-road plans scuttled and an hour to kill, I decided to have a play with my make-shift camber gauge. Amazing how easy it is to adjust -- I now have 1.5 degrees negative on each side.. a major improvement over the 1 deg negative / 0.75 deg positive with the standard arms

Oh, and the only other thing: Getting 150 ft-lbs of torque on the drive shaft nut is not a very nice job. Getting the split pin holes lined up once it's torqued is even less fun. Let us never speak of this again