Hi All,

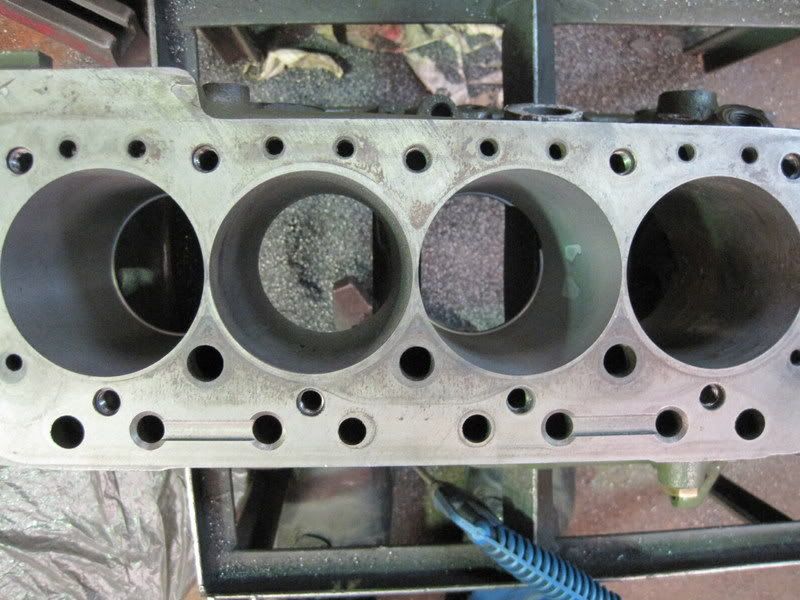

Here are some photos showing the wall thickness on a 1380 A+ block. The difference in wall thickness is from poor manufacturing. The sand core's were not put in squarely in the core boxes when casting.

The measurements are from across the block "width"

The thinner side being the front of the block (dizzy side)

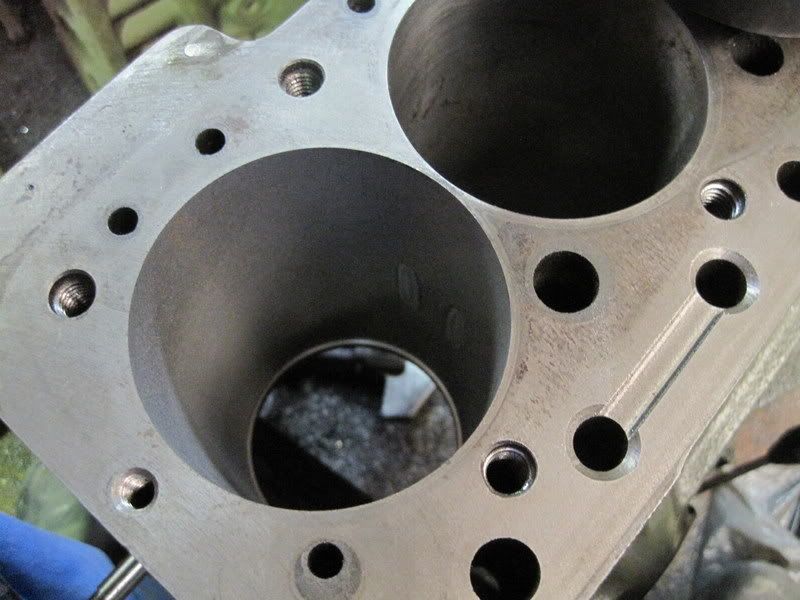

This is the first hole bored ready for the sleeve, note the step in the bottom that the sleeve sits on so it can't move. Also note the two pieces of steel in the bore (in the middle of the picture) that hold the sand cores in place when casting.

I put the sleeves in these two first (1 & 3) then do 2 & 4 because this was a 1380 block and had to be bored back to 1380 for this customer as they already had the pistons for it.

This is the finished product sleeved and ready to go.

Some people think i work alone but i have a nightshift that comes in but i have to feed them first before they'll work! Some even bring their children in to help

This is batty, he hangs around overseeing the work.