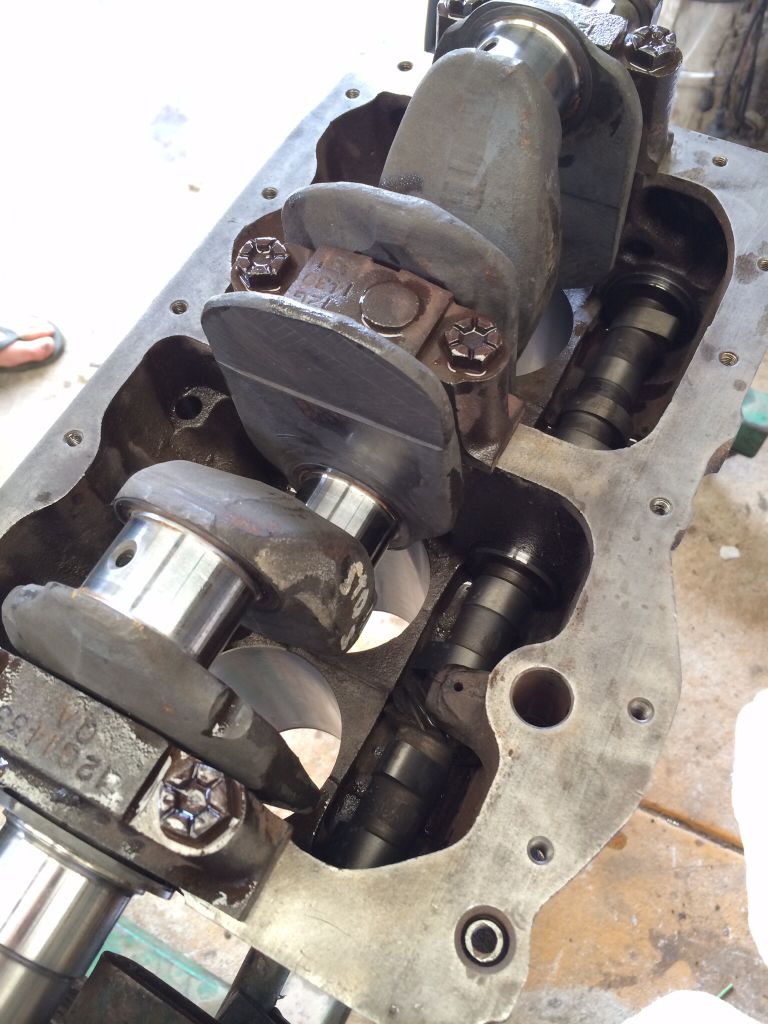

After five months of procrastination I finally got some motivation from Rodney (Boomini) and my build is underway. I've gone with the .06 over bored block which I've had chemically dipped and the bores honed. The head has been fully reconditioned with new value stems and the oversized valves seated, the crank has been balanced along with the flywheel. The pistons have been press fitted to the rods and balanced. The cam is from Wade Cam with the 104 profile.

I purchased $2000 worth of various parts including bearings, push rods, cam follower, timing chain, copper head gasket, a CNC rocker with roller tips, oil pump, .06 Hypertec pistons and Hasting rings, VHT paints (primer, bright red & clear coat) to list the items I can remember!

I realised after doing my research doing my first engine build myself was going to be far too hard so with the help of Rodney (who I now refer to as BME - BooMini Engineering) I'm underway

and by help I mean Rodney is doing it all and I'm annoying the crap outta him with a thousand questions per minute!

Progress to date:

Today the pistons were fitted only to find they protruded beyond the block by .68mm so a mad dash back to the machine shop (Performance Modification - Osbourne Park) and with .035 skimmed off the pistons take two of fitting the pistons will occur in the morrow

Watch this space for updates